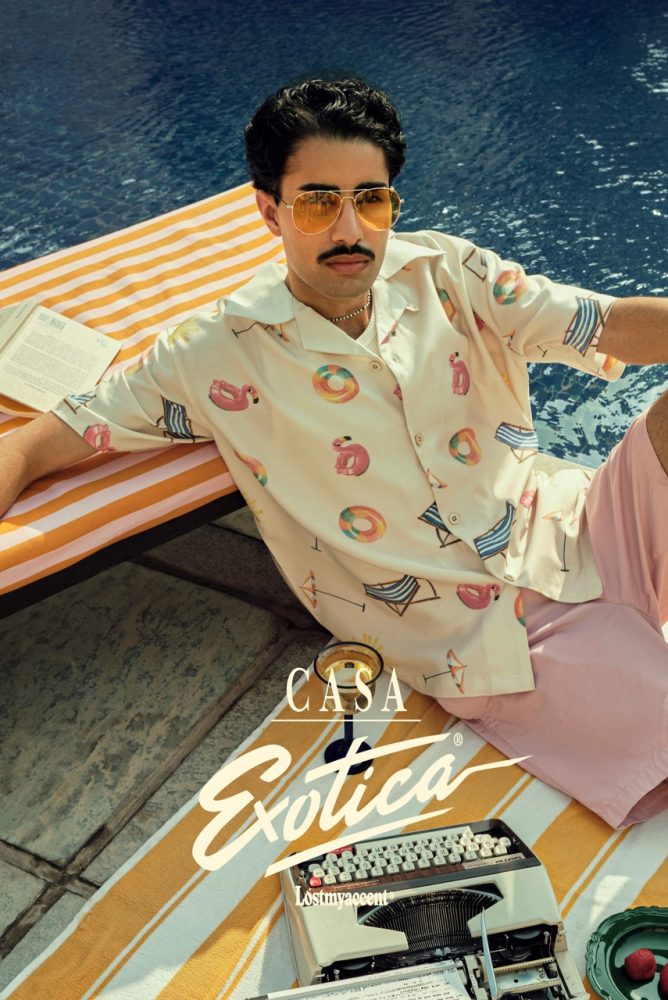

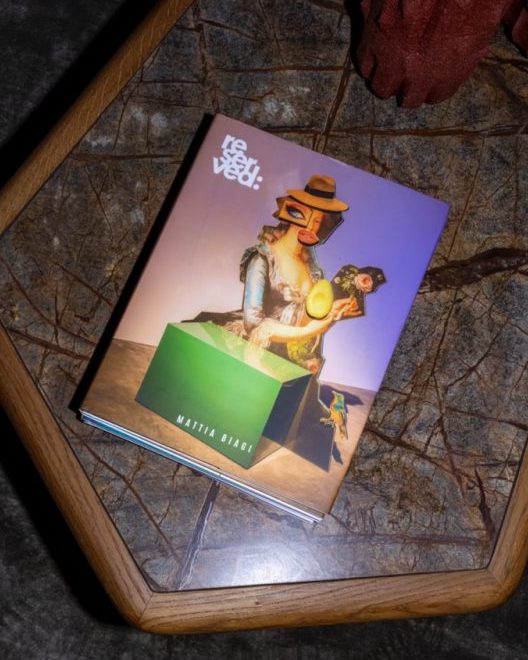

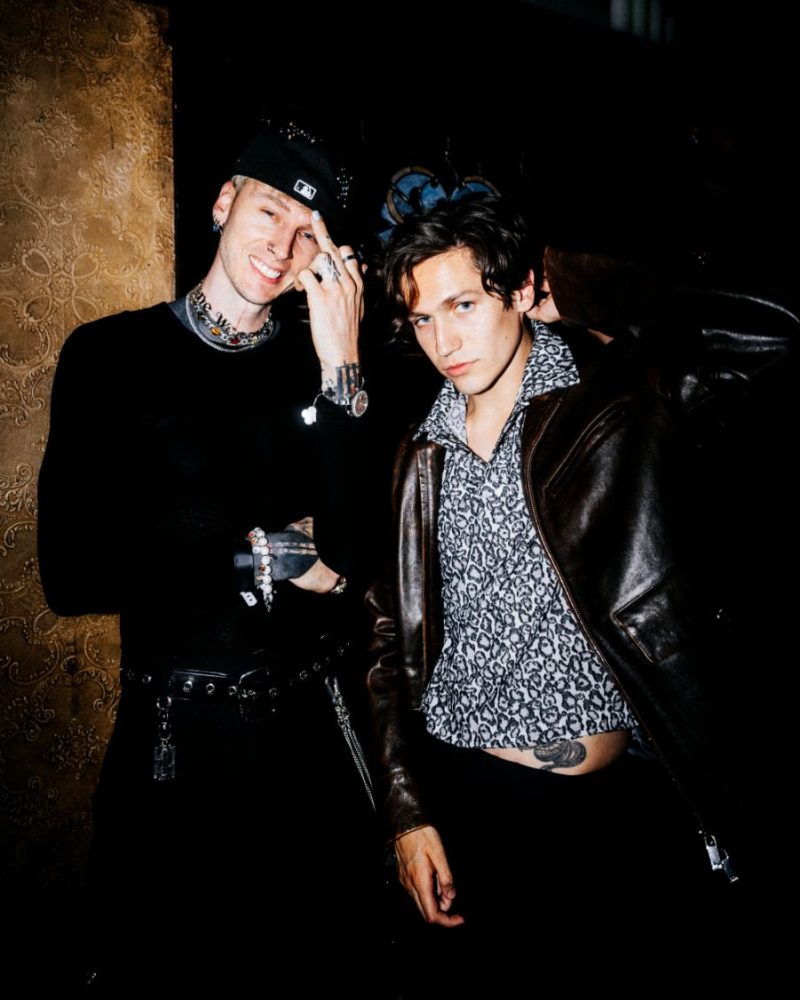

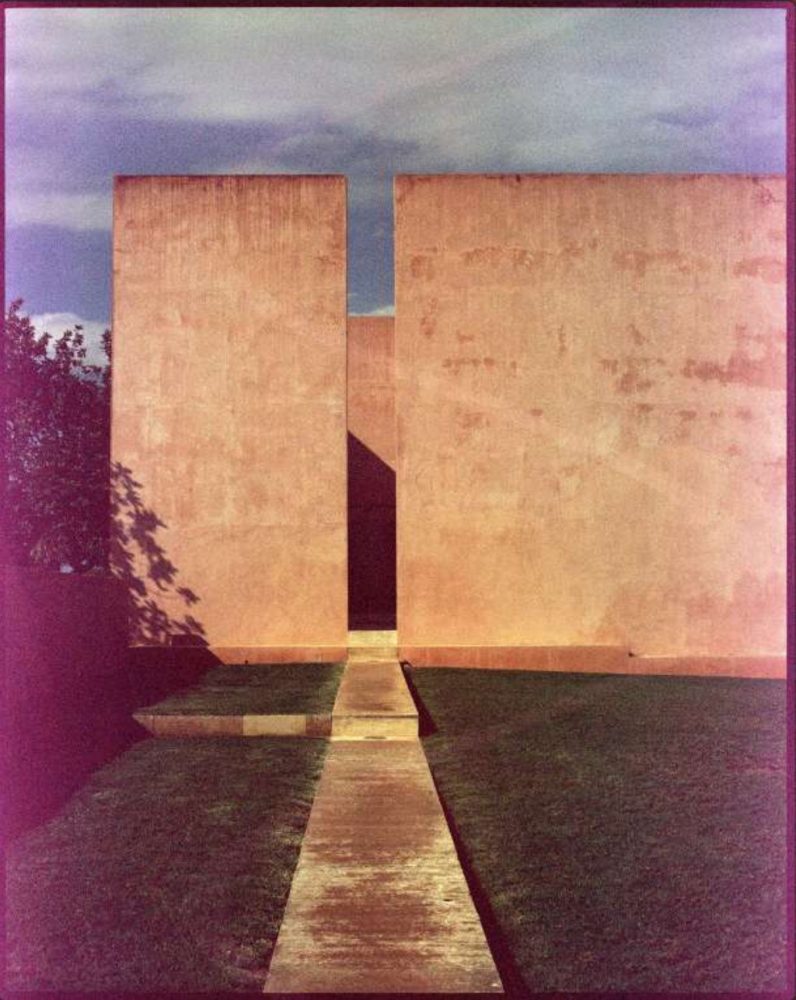

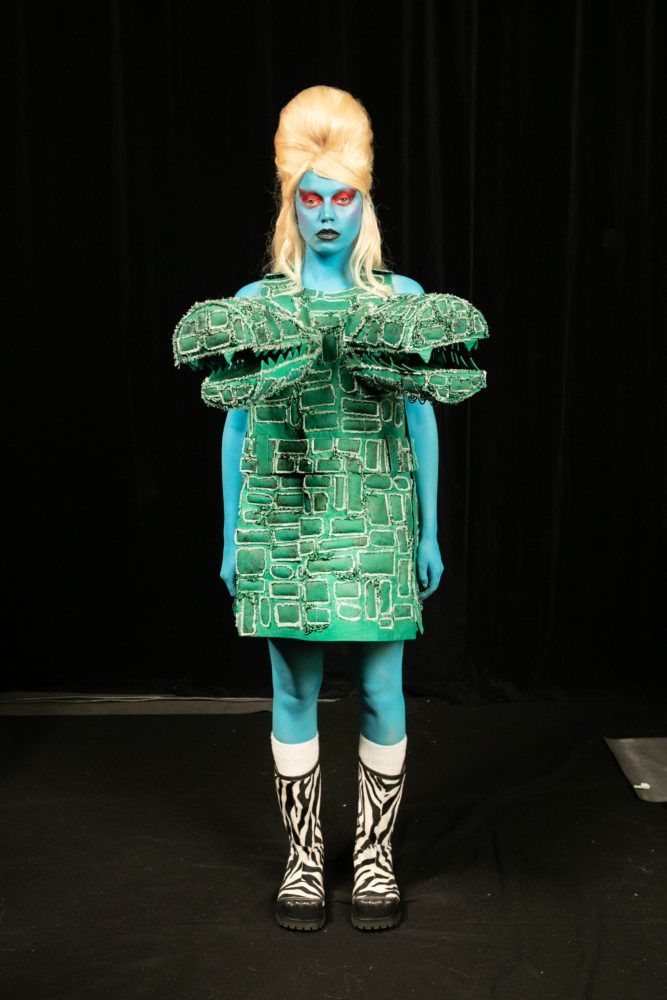

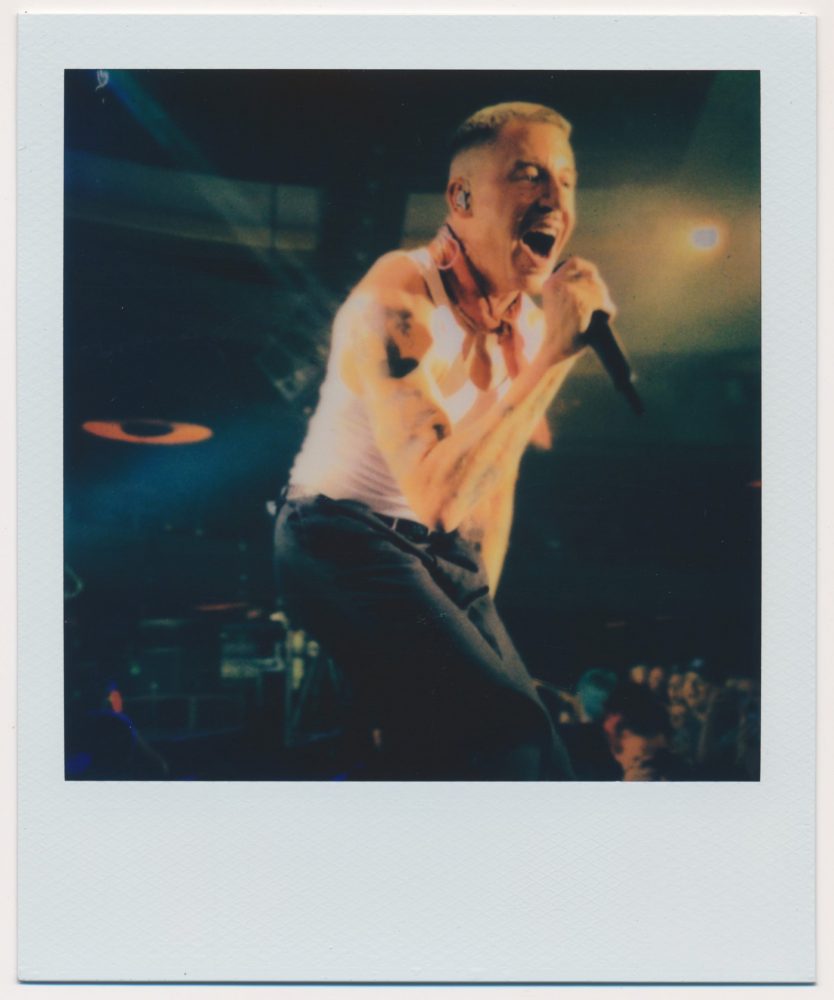

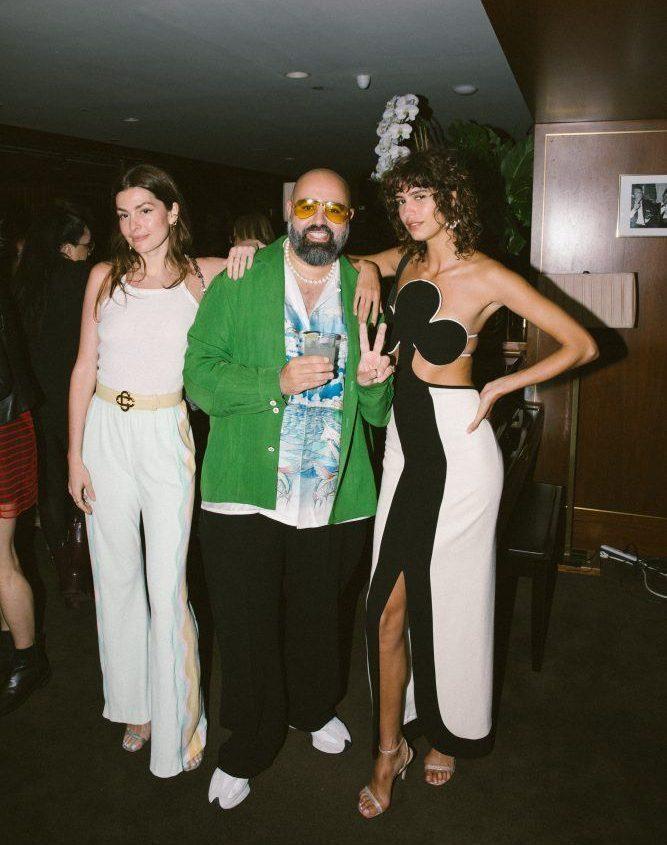

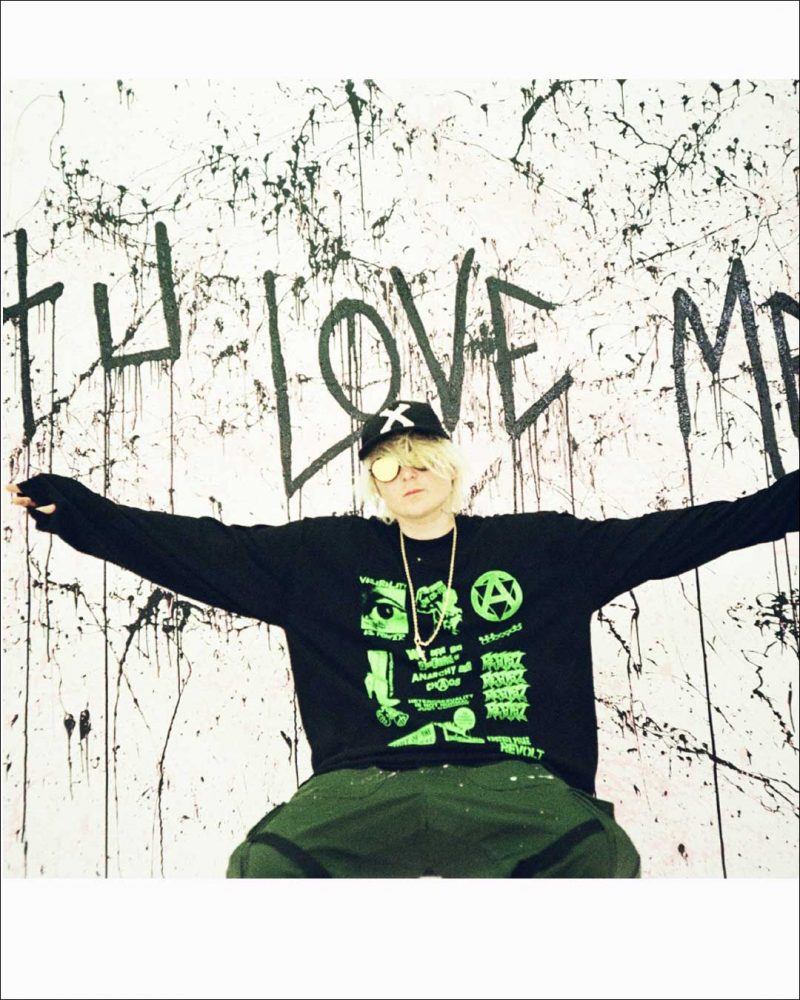

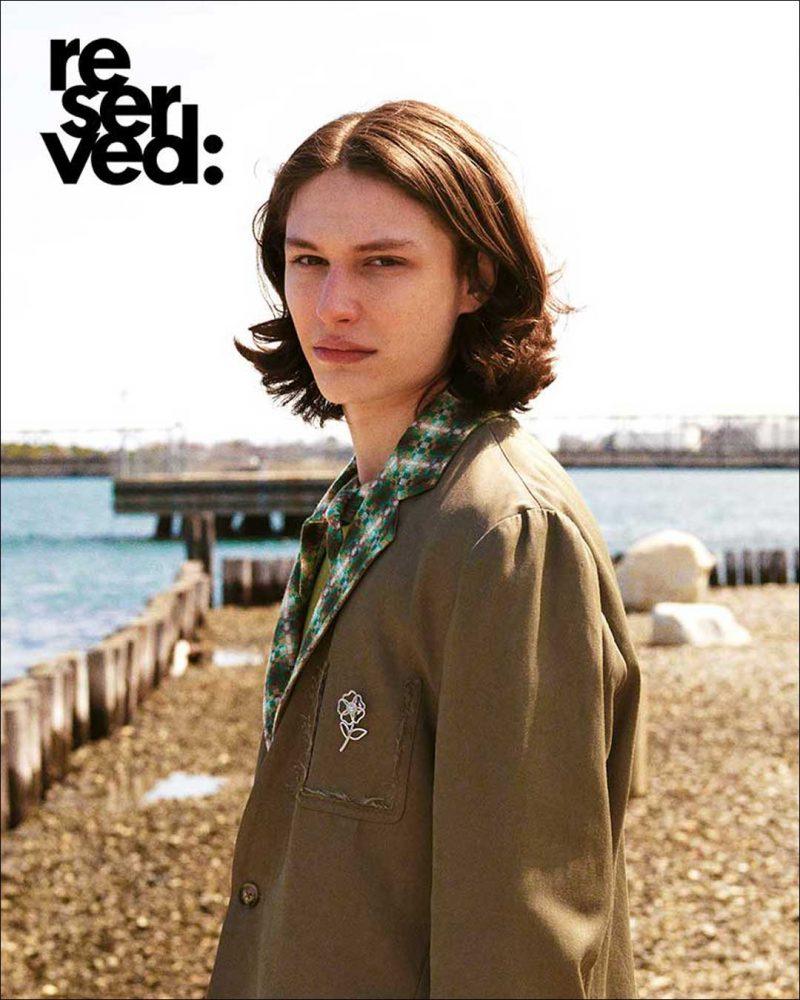

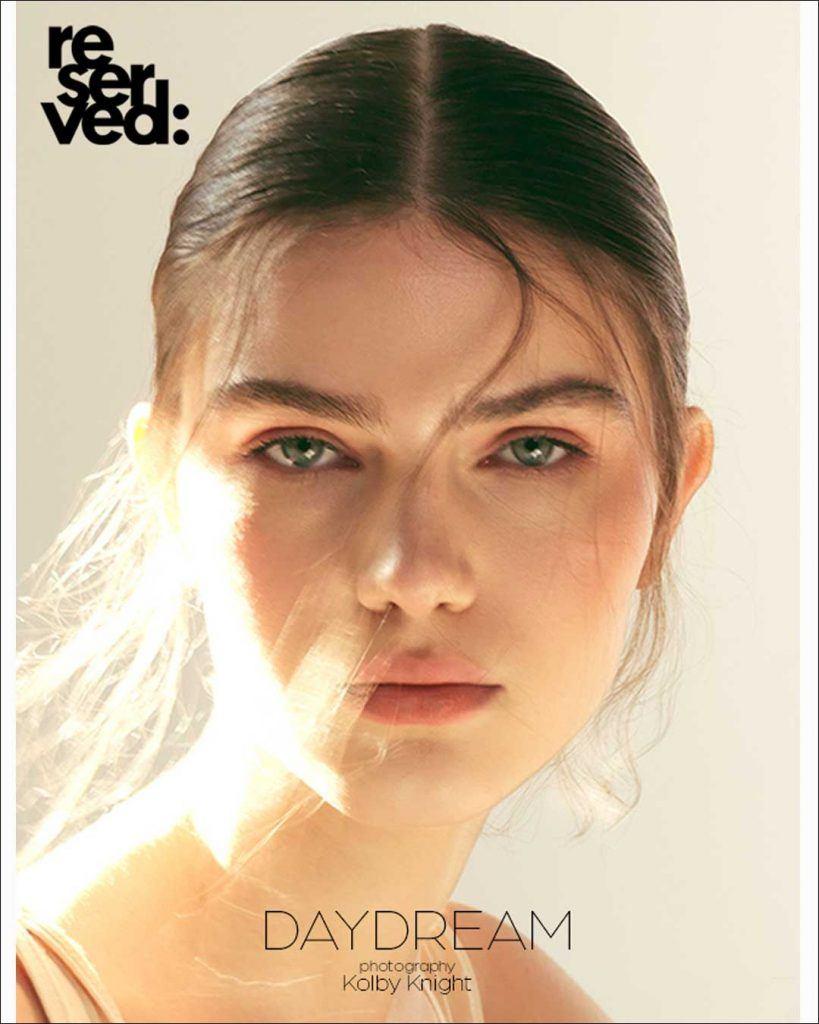

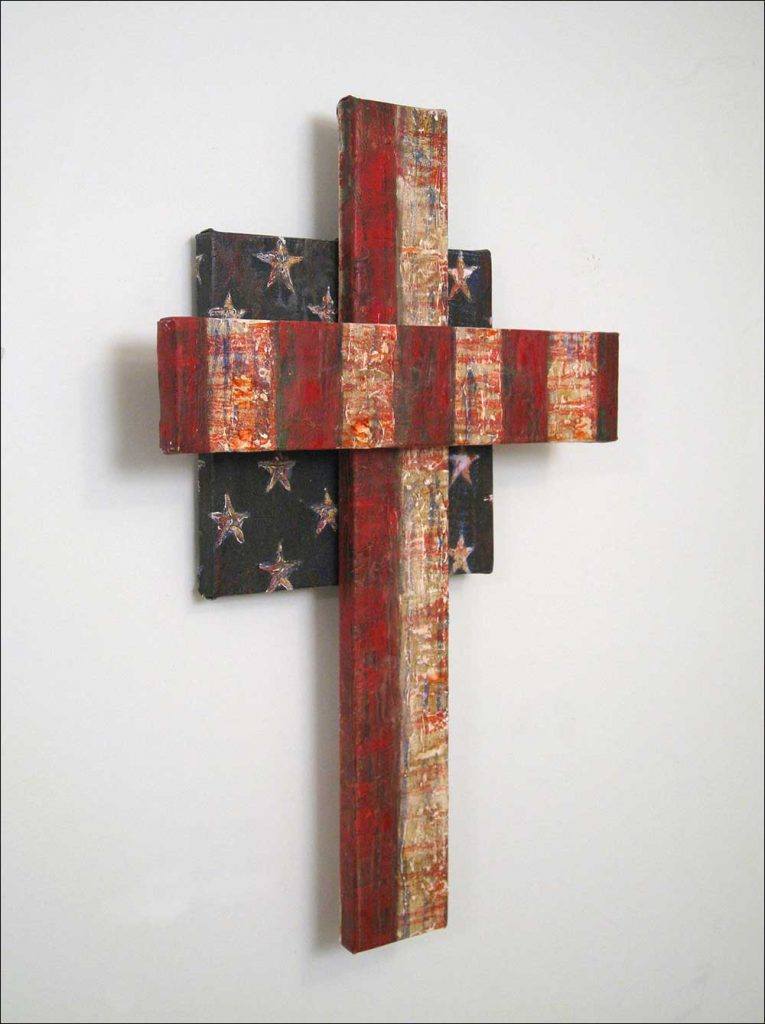

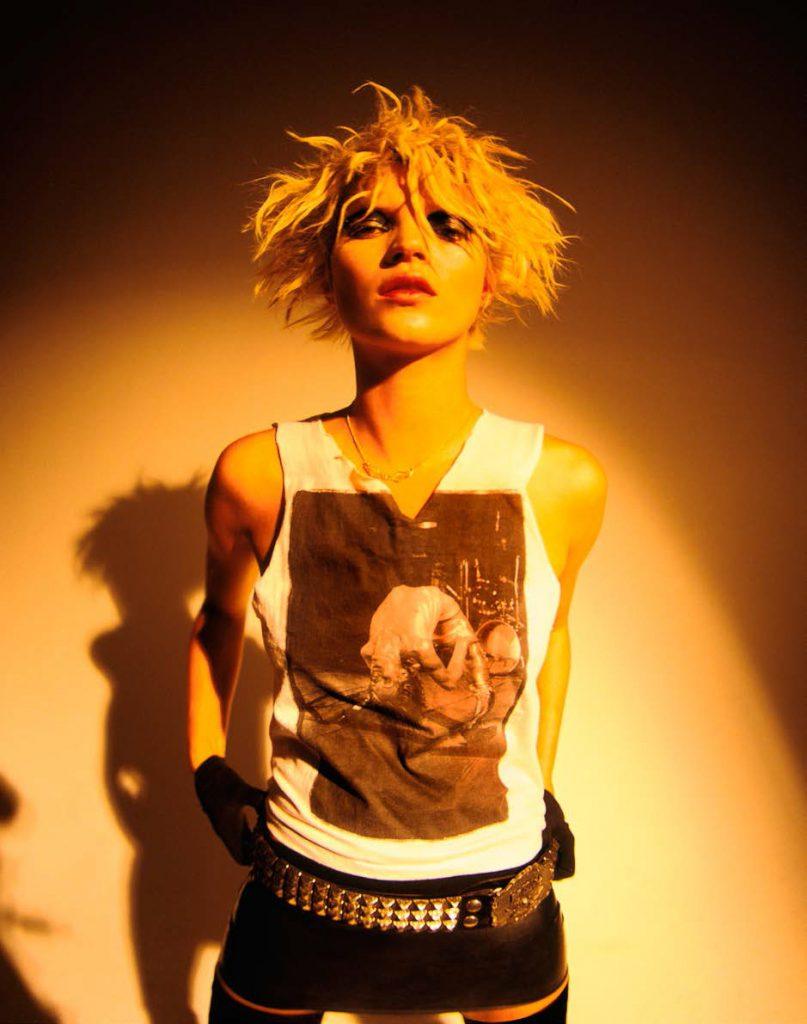

- Photo Courtesy KHOLA.

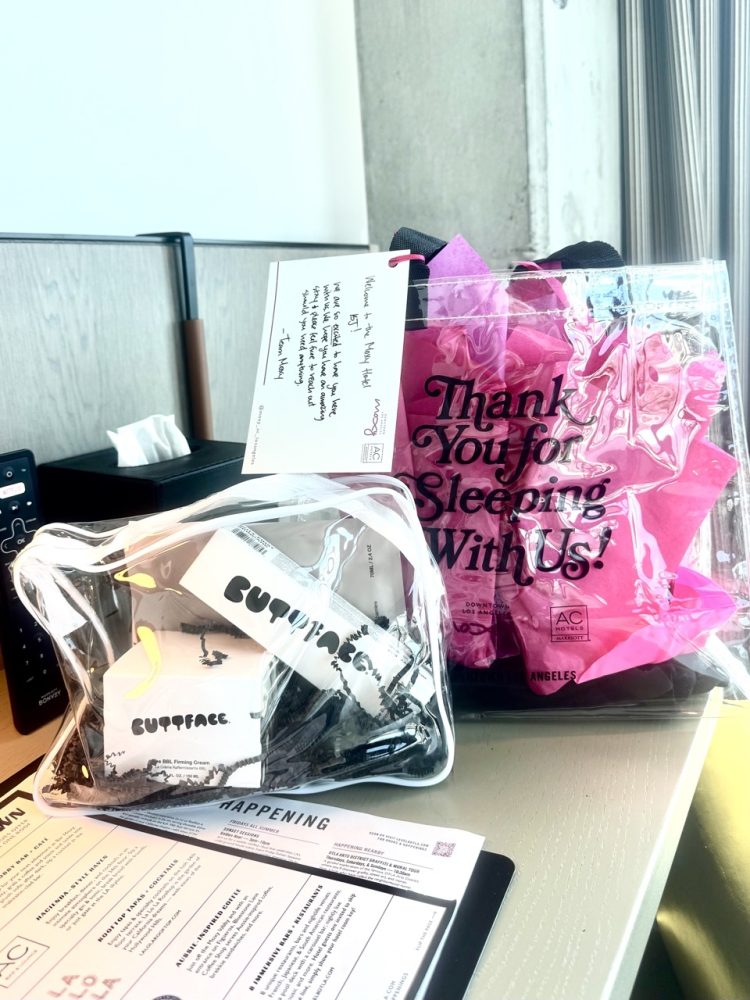

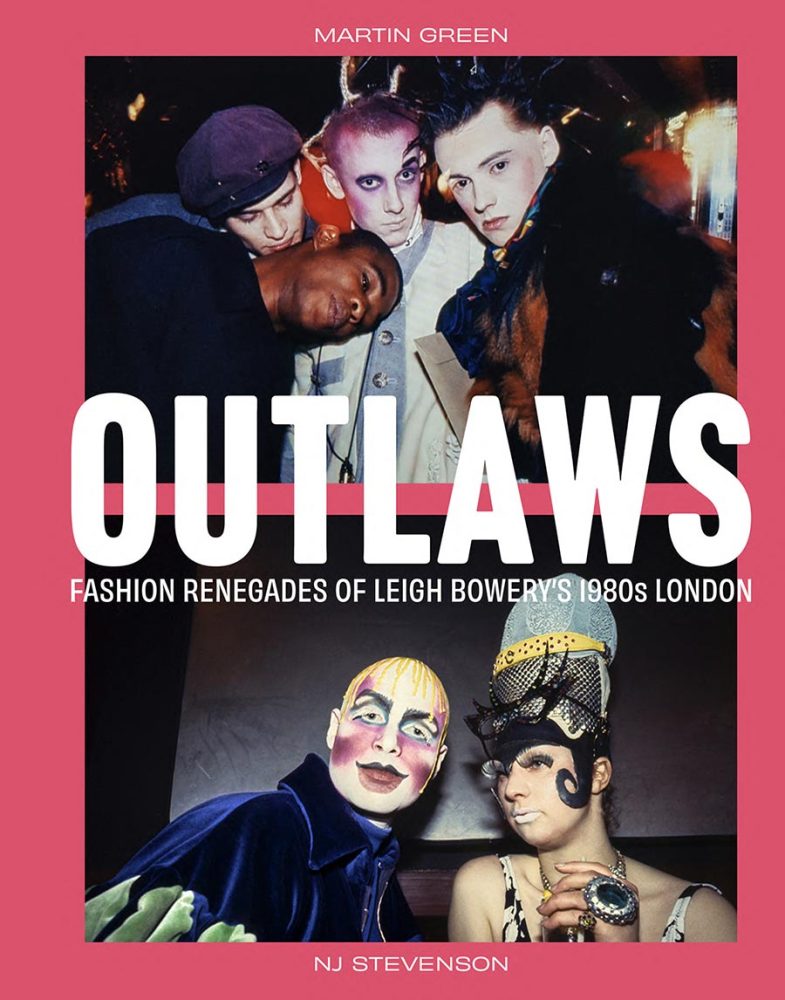

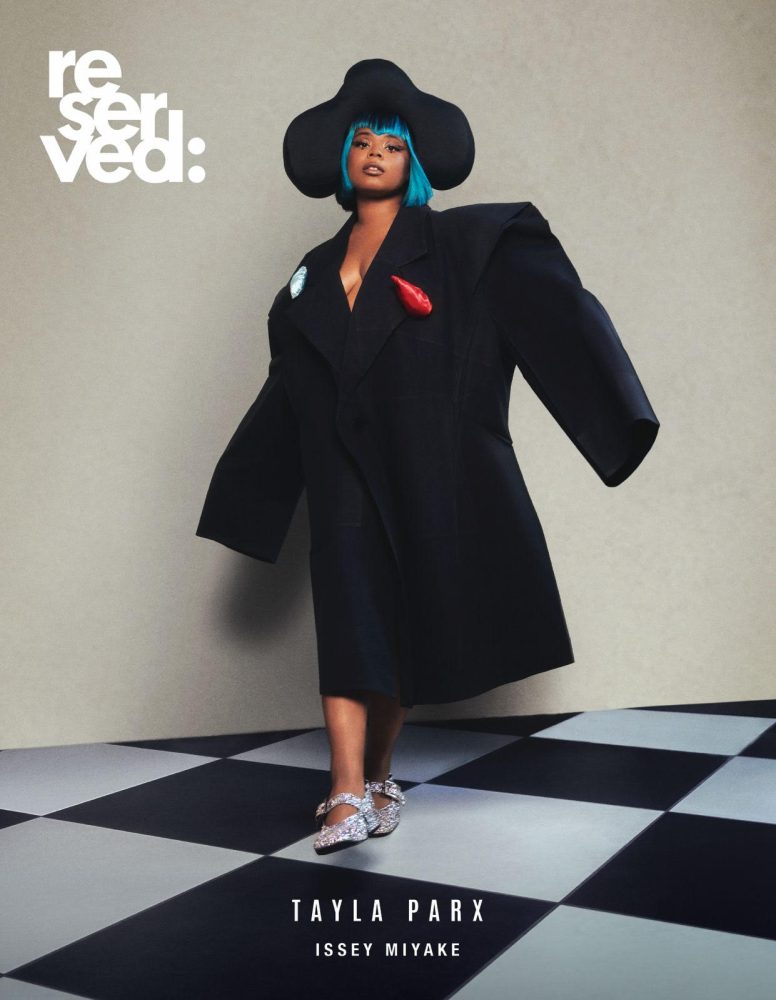

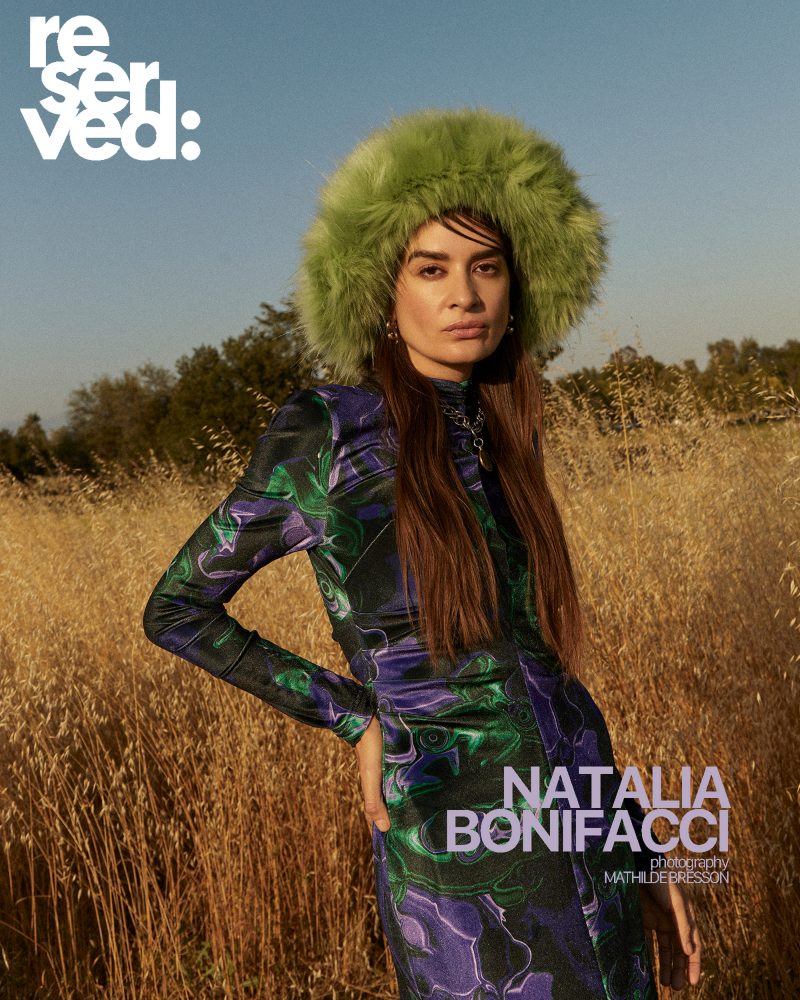

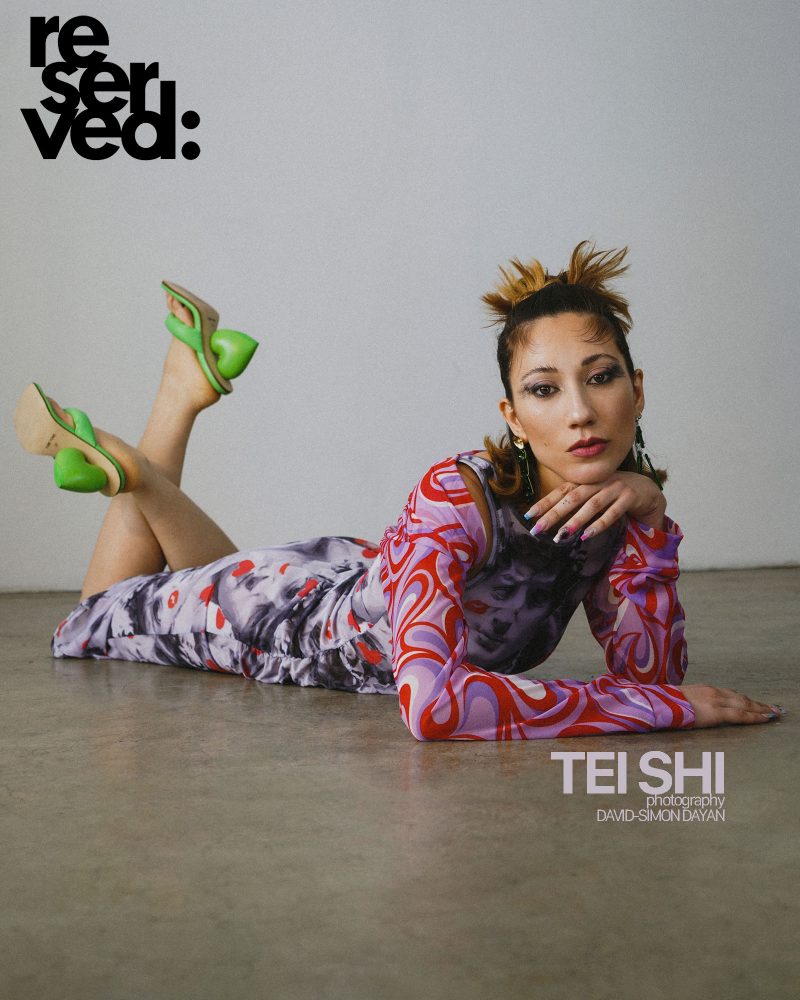

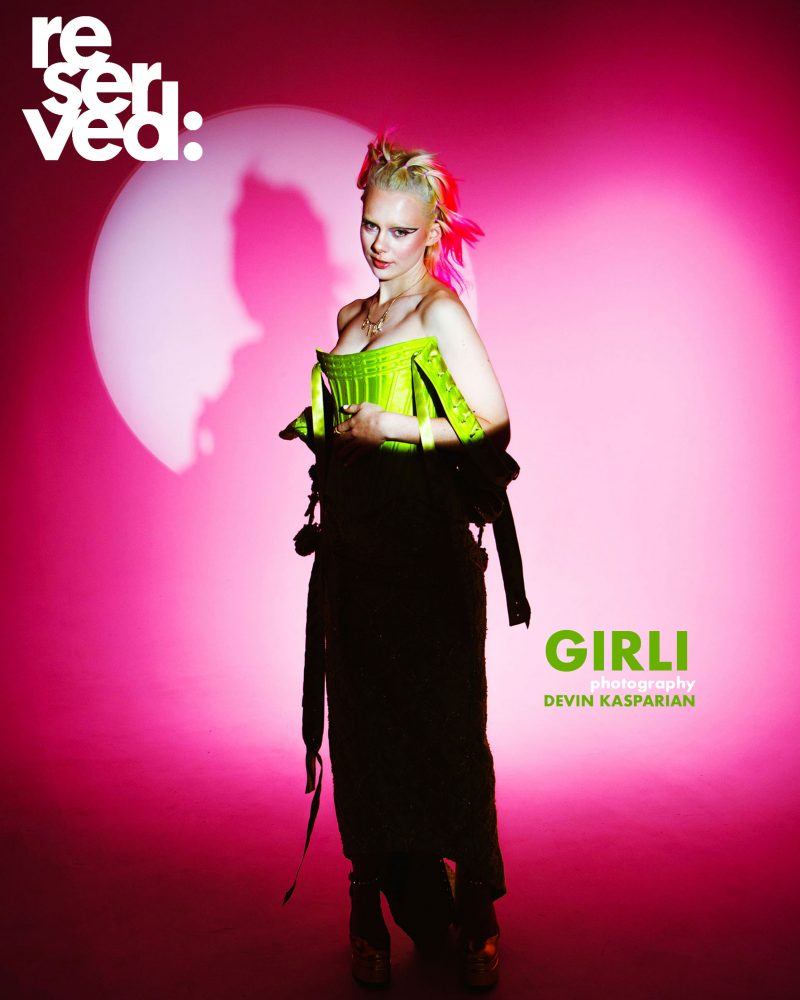

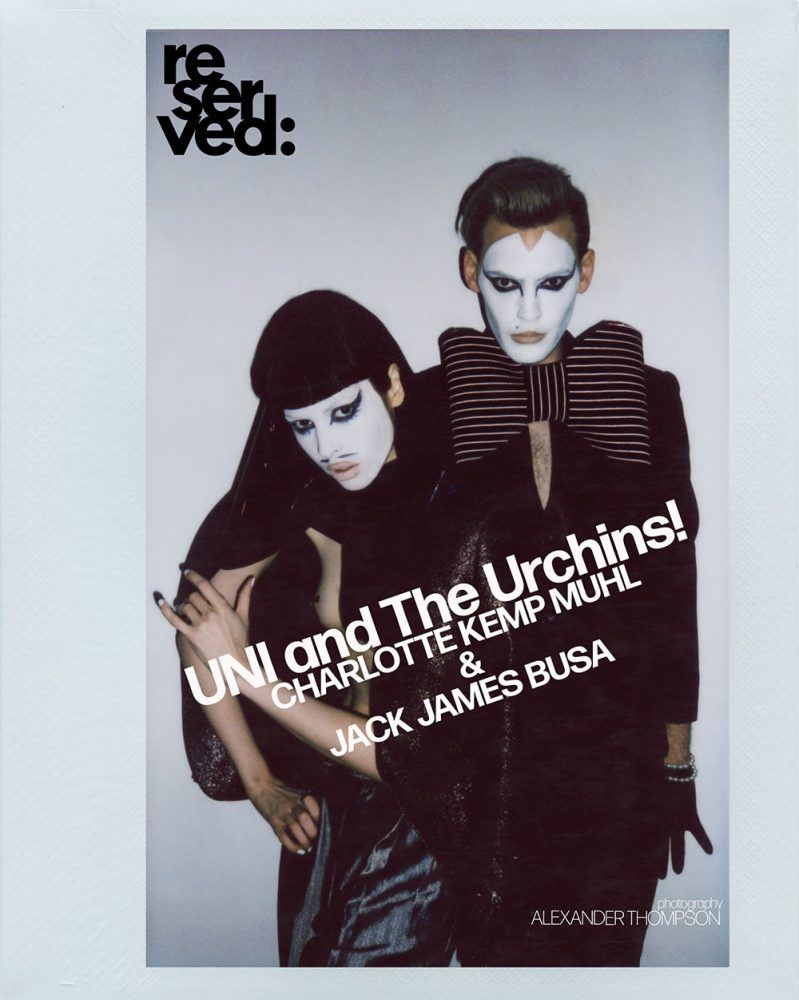

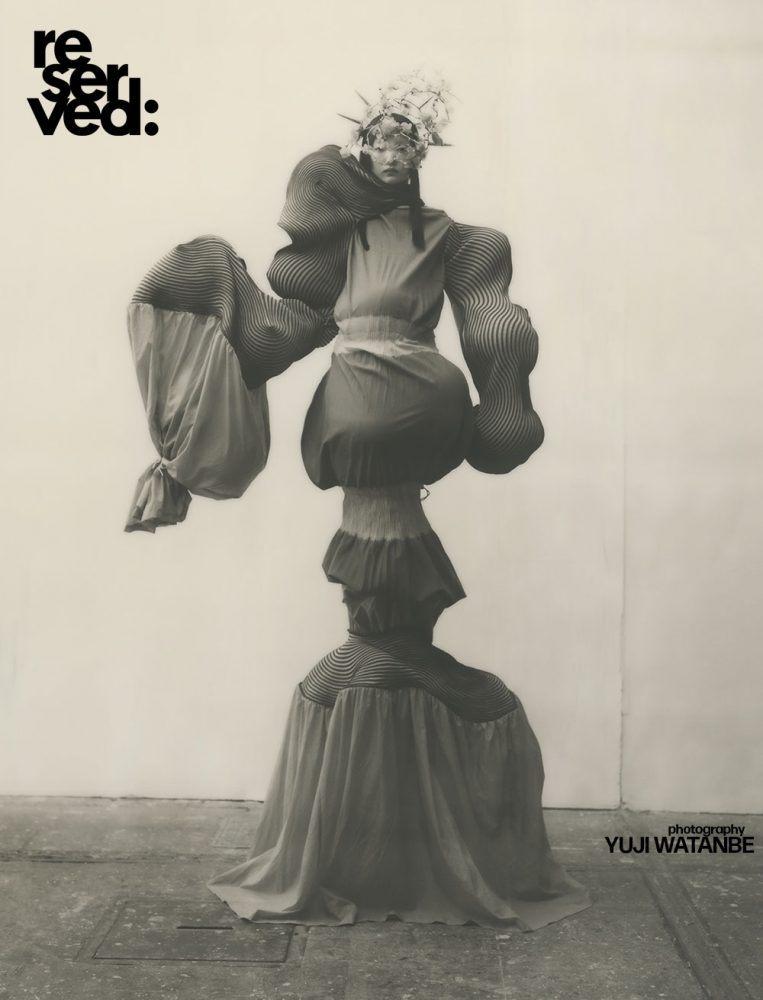

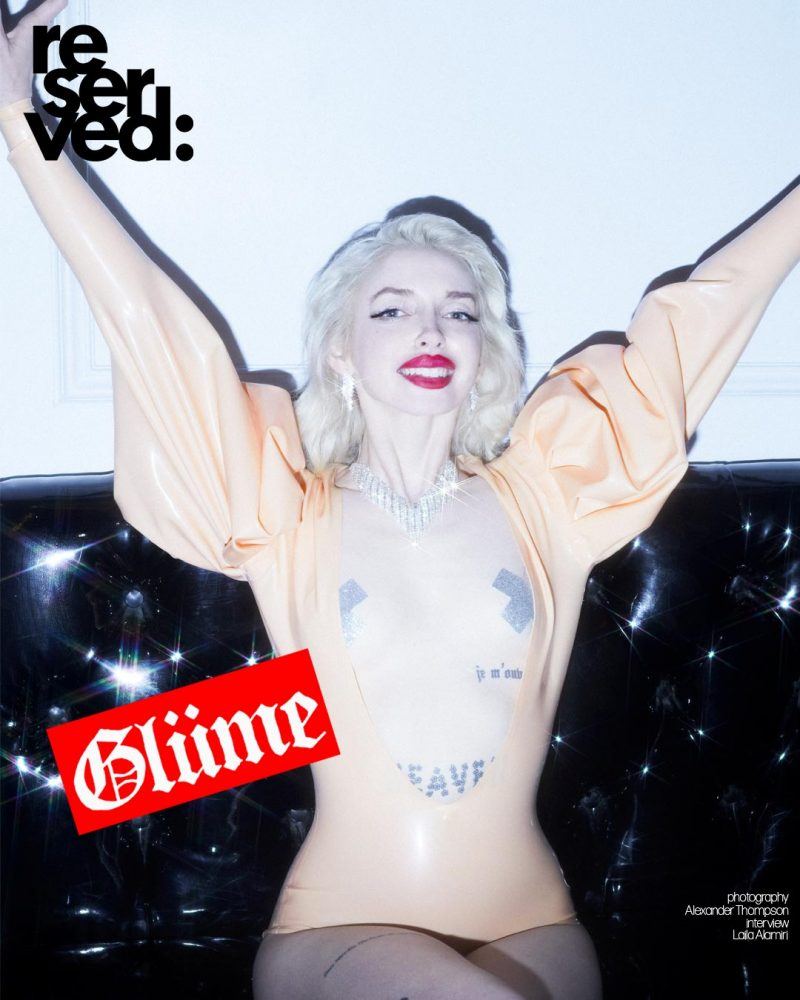

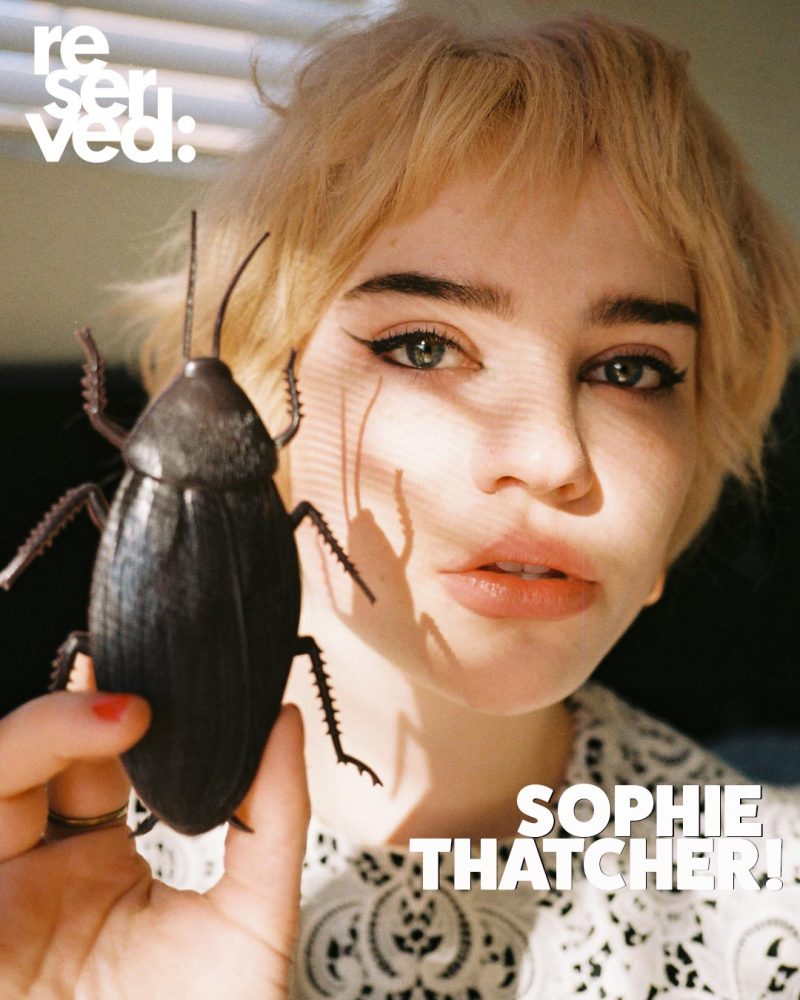

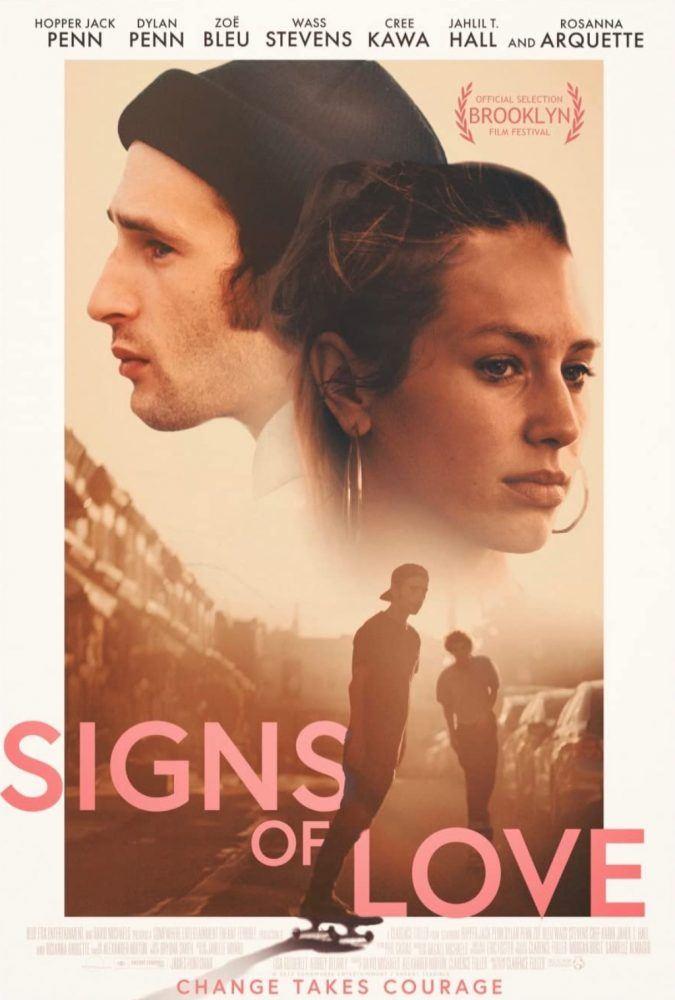

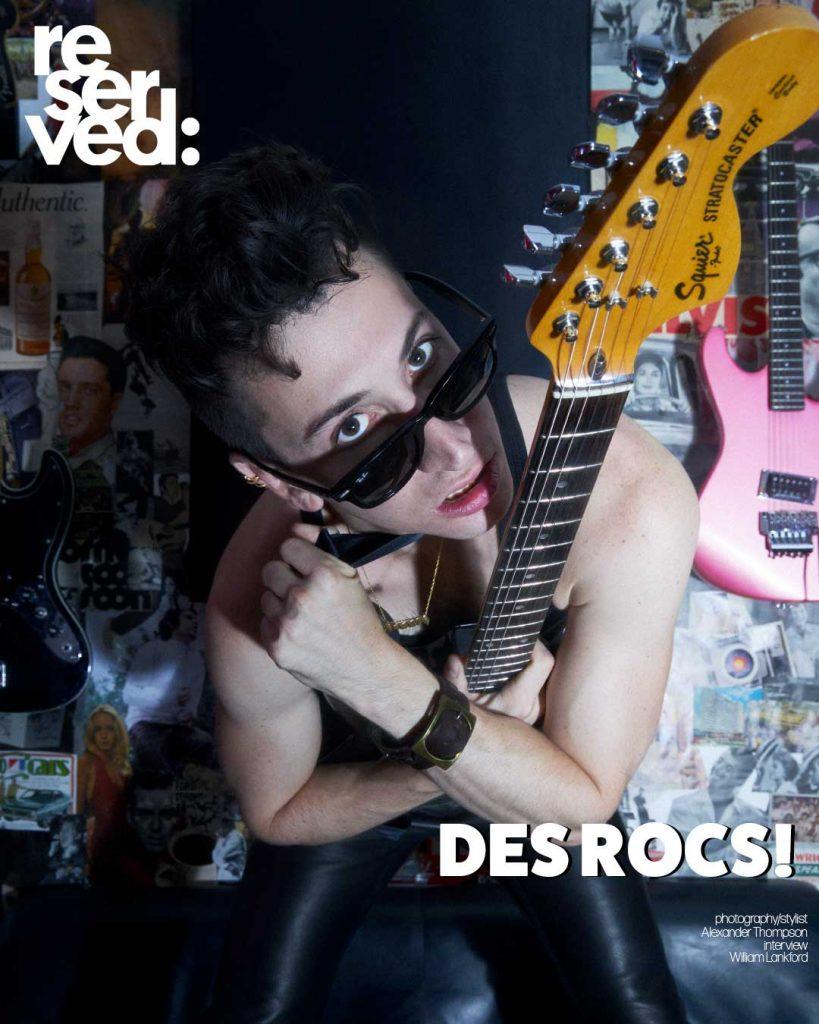

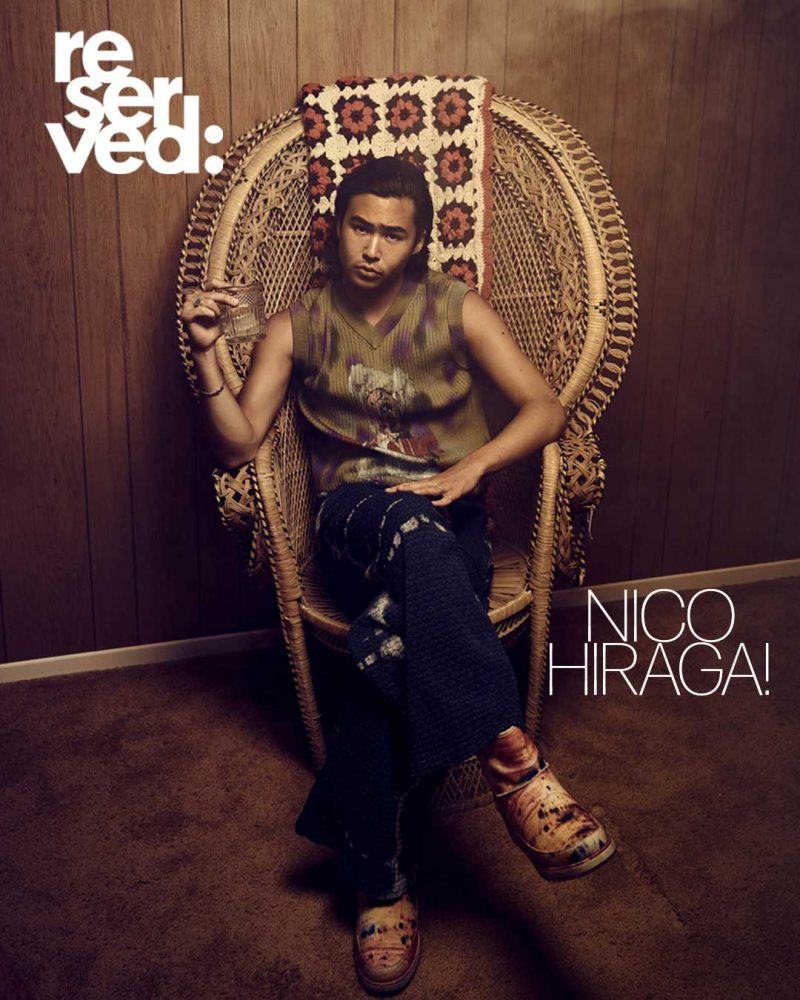

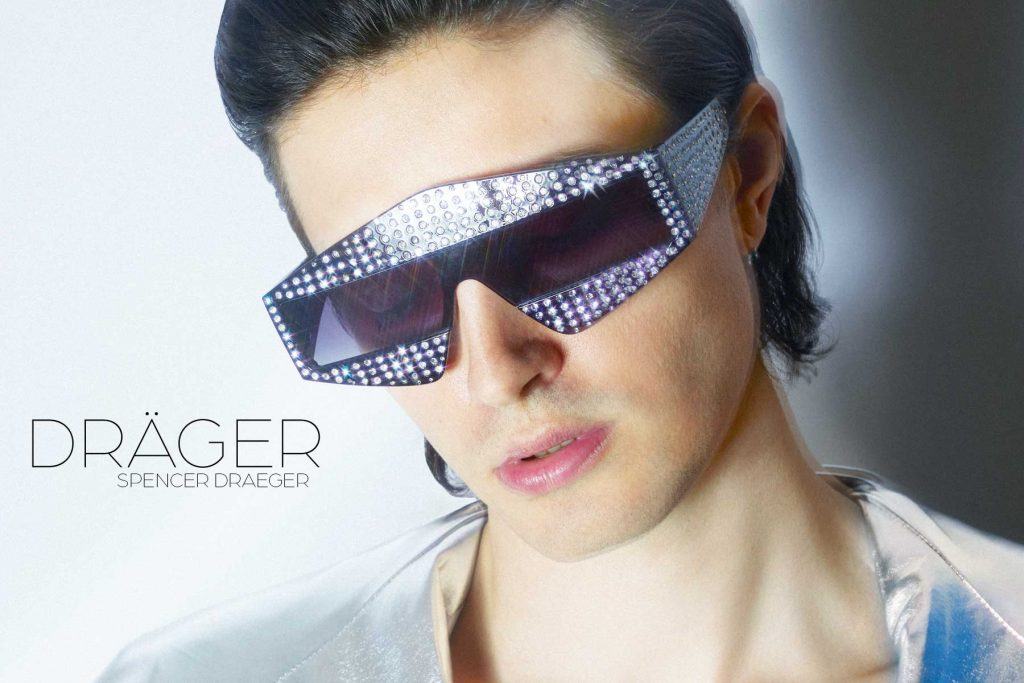

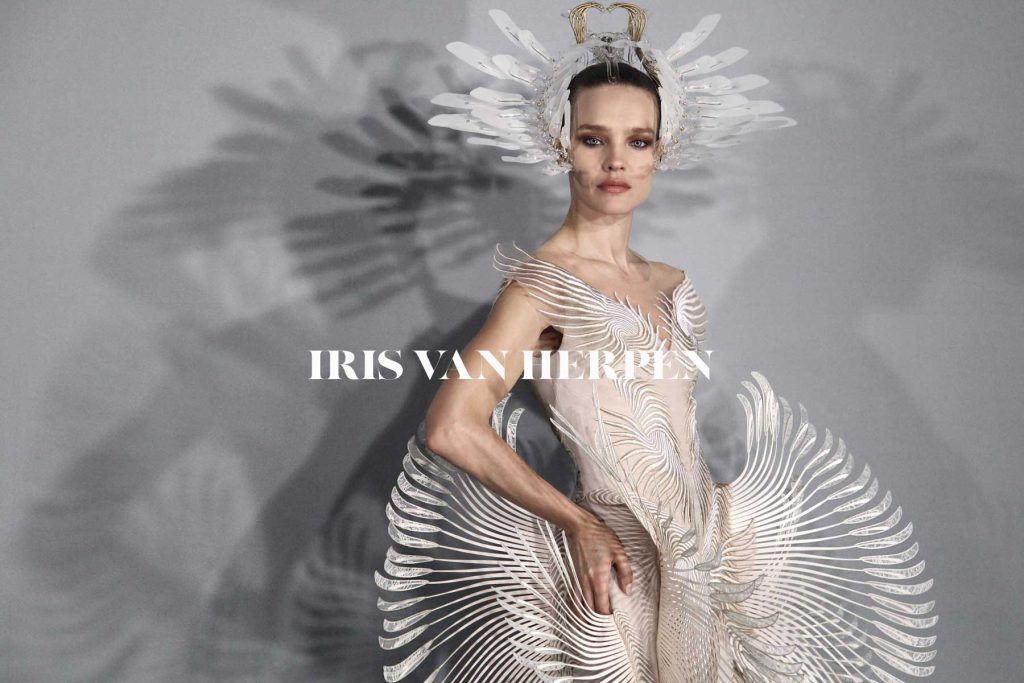

There’s a new name stepping into the future of footwear, and it’s called KHOLA. Freshly launched, the brand is built around a radical idea: a modular sole system designed to extend the life of shoes and close the loop on fashion’s endless cycle of waste. More than just another sneaker drop, KHOLA arrives as a design solution, an experiment in circularity that feels as timely as it does forward-thinking.

The vision comes from Rem D. Koolhaas, the creative force behind United Nude, who found inspiration during a design meeting with ISSEY MIYAKE in Paris. Posed with the deceptively simple question, “What is the shoe of the future?” Koolhaas flipped the script, stripping footwear down to its essence. Rather than styling for the sake of aesthetics, KHOLA pivots to engineering as design, reimagining what it means to build a shoe from the ground up.

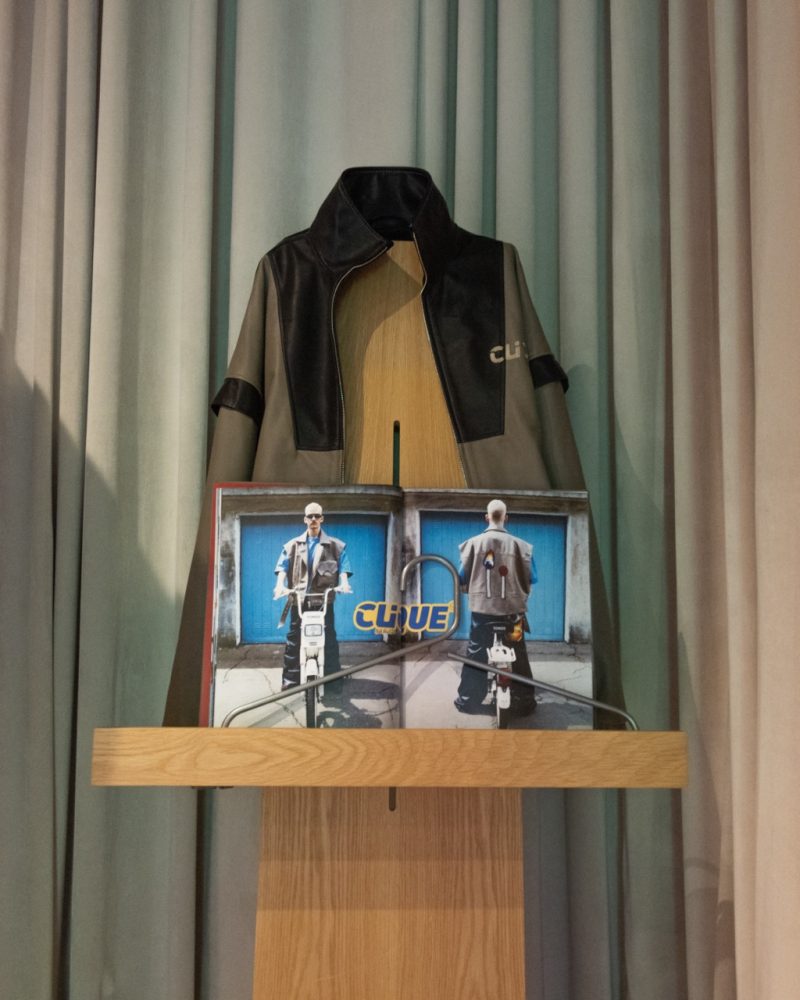

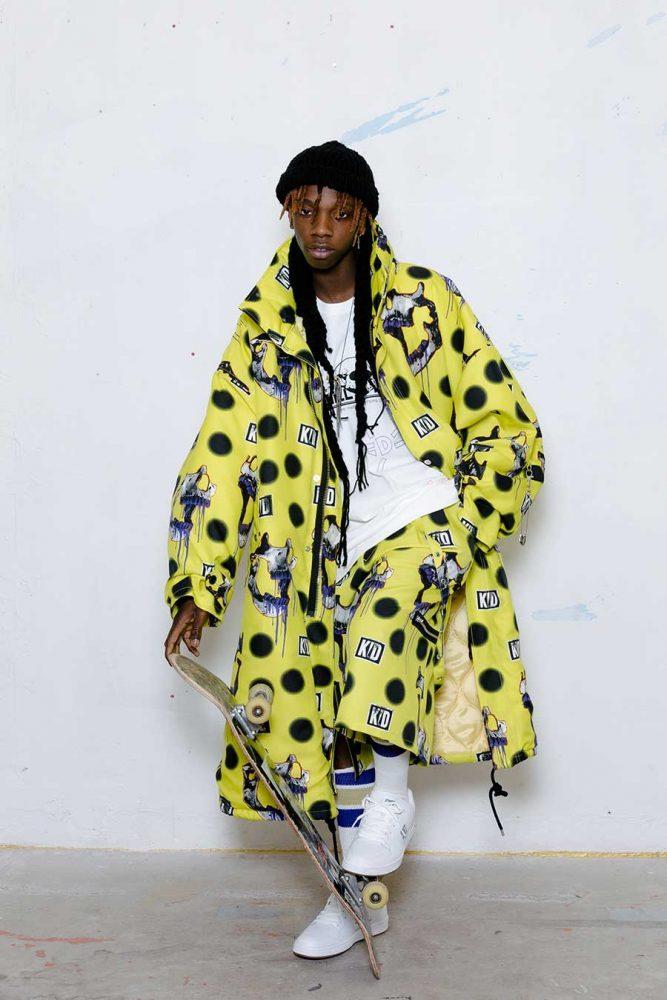

KHOLA’s shoes are modular and require minimal tools, making them versatile for collaborations. The brand, based in LA, emphasizes local production for sustainability and flexibility. Future plans include repurposing dead stock from major brands to reduce waste and localized manufacturing expansion. Unique modular design and commitment to sustainability set it apart, offering a potential solution for other brands to adopt eco-friendly practices.

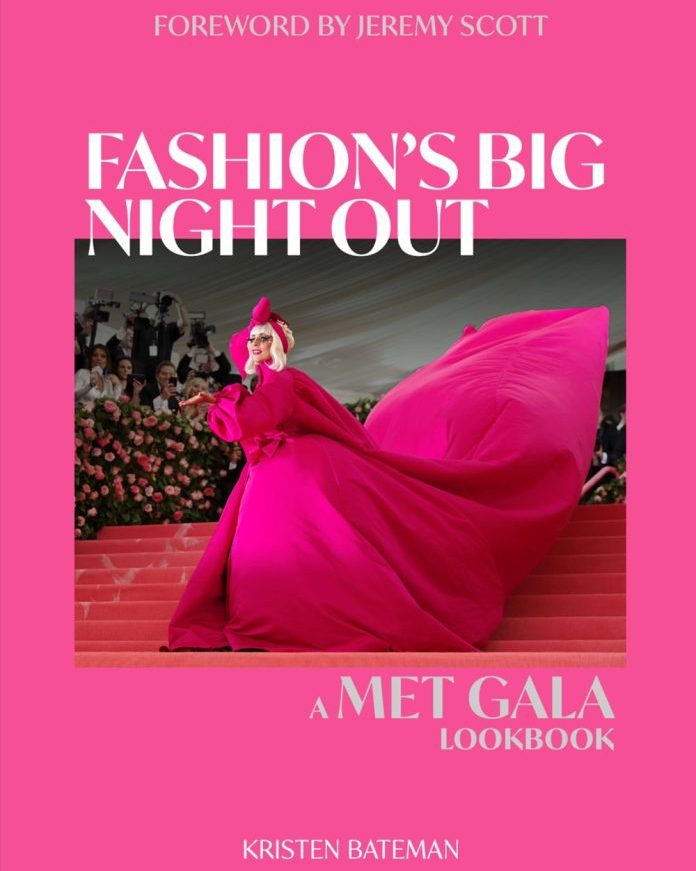

At the heart of KHOLA is a patent-pending, glueless construction system that makes every component removable, customizable, and renewable. The debut drop introduces three sleek colorways of its first style, a digital configurator for online re-soling and personalization, and KHOLABS, a series of limited-edition experiments that showcase the system’s potential. With its modular DNA and sustainable ethos, KHOLA isn’t just a new footwear brand, it’s a blueprint for the next era of design.

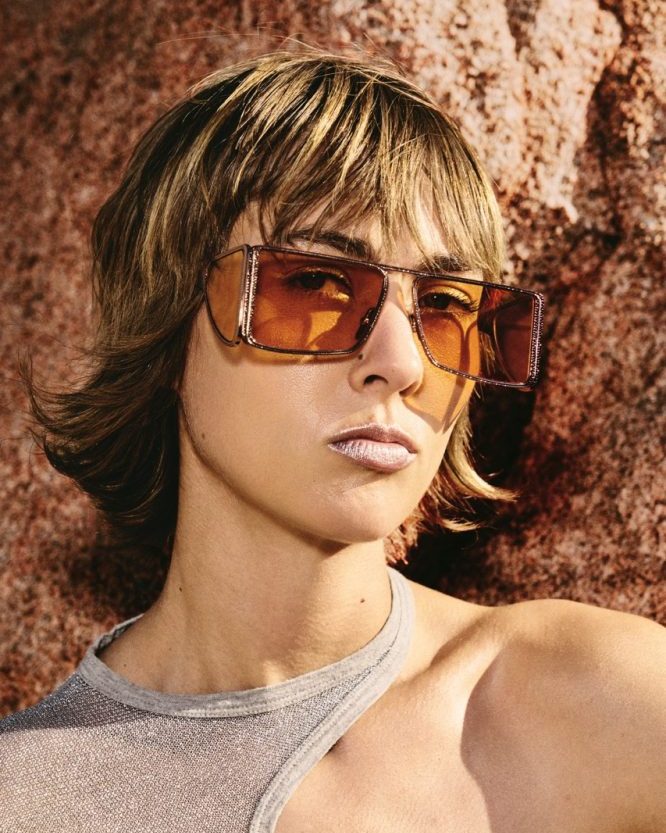

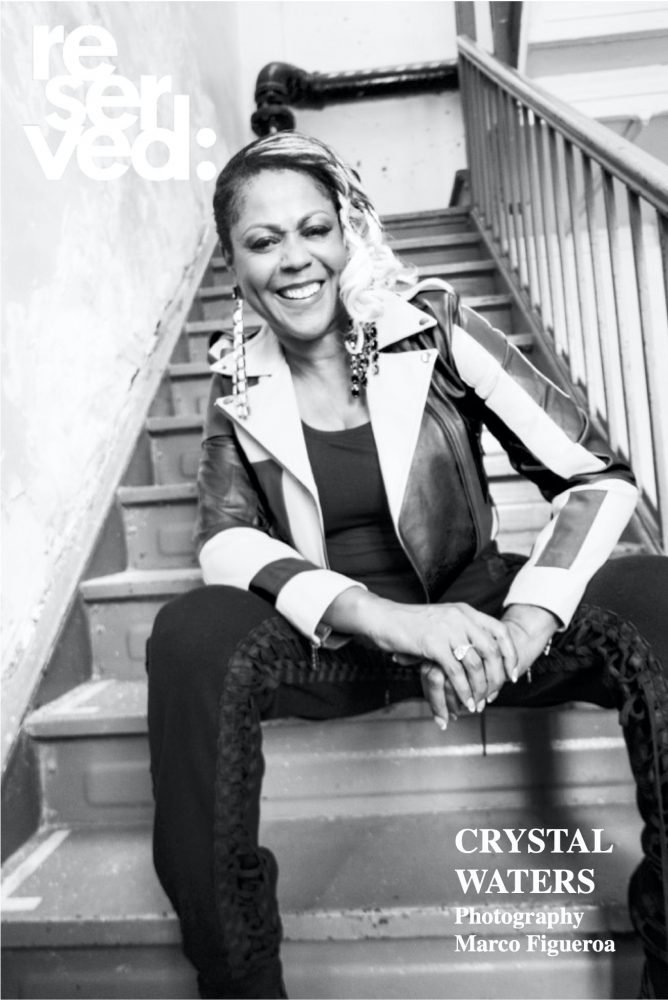

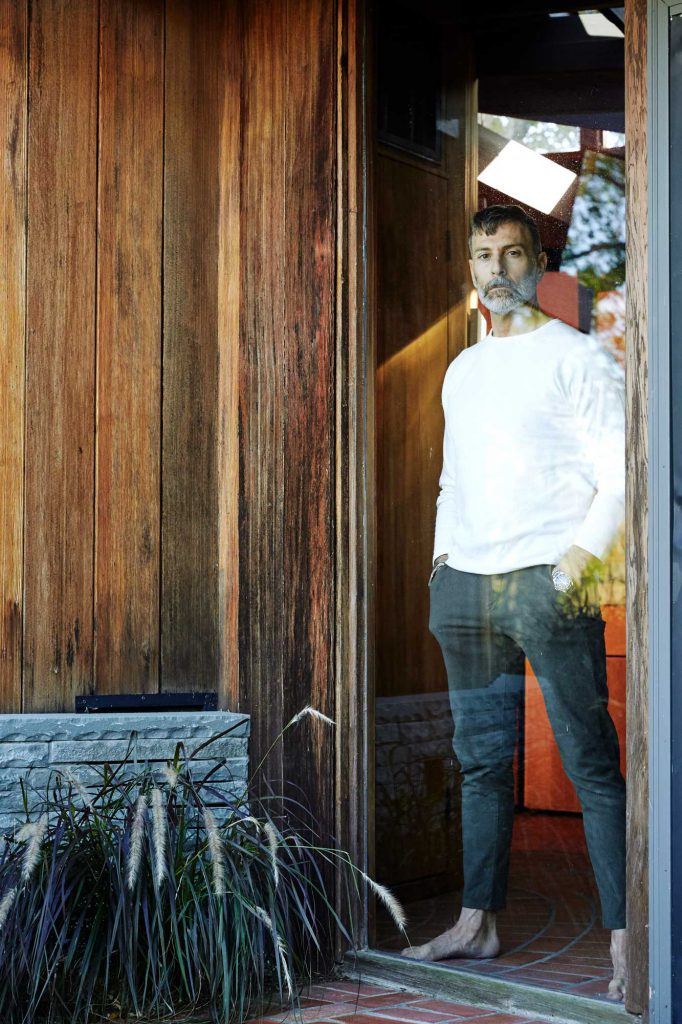

- Photo Courtesy KHOLA.

- Photo Courtesy KHOLA.

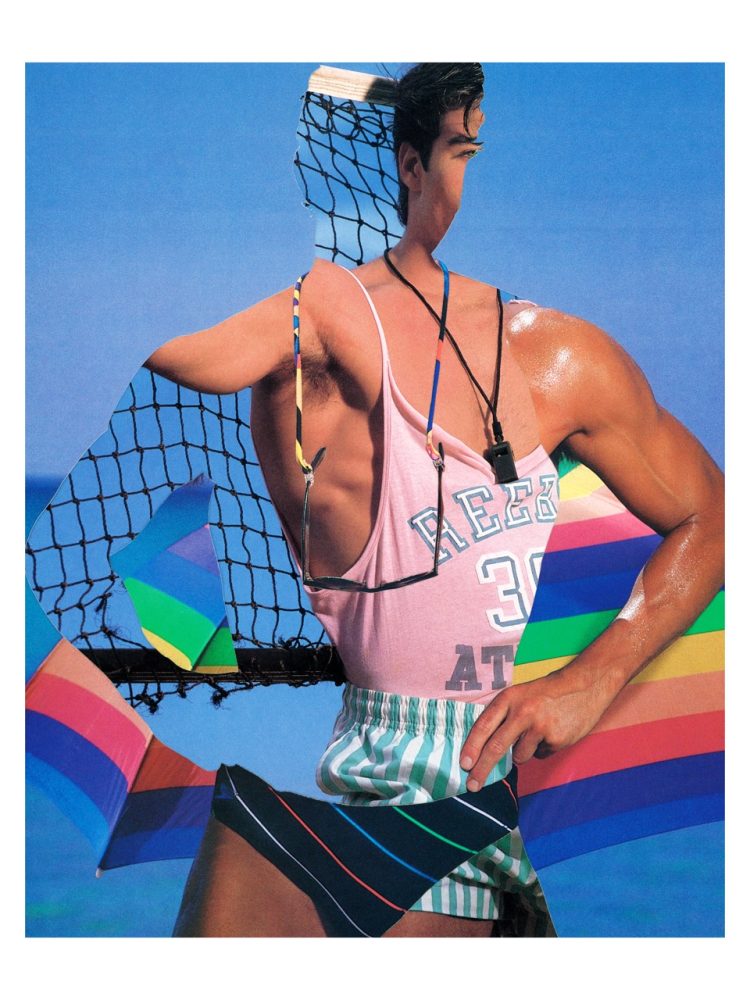

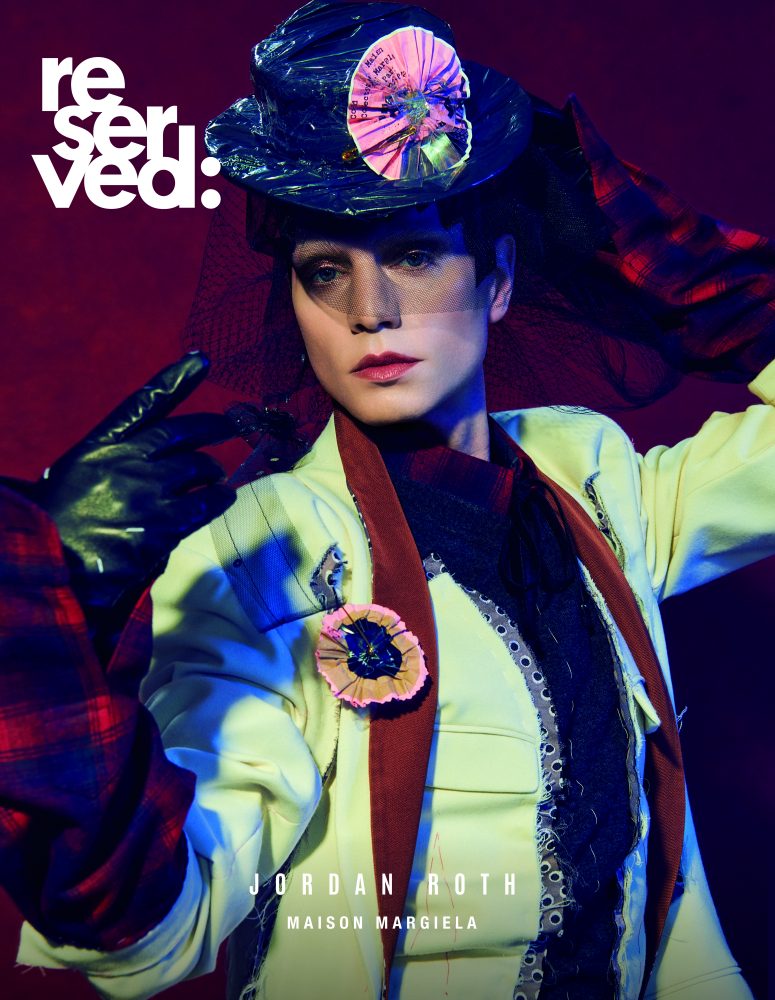

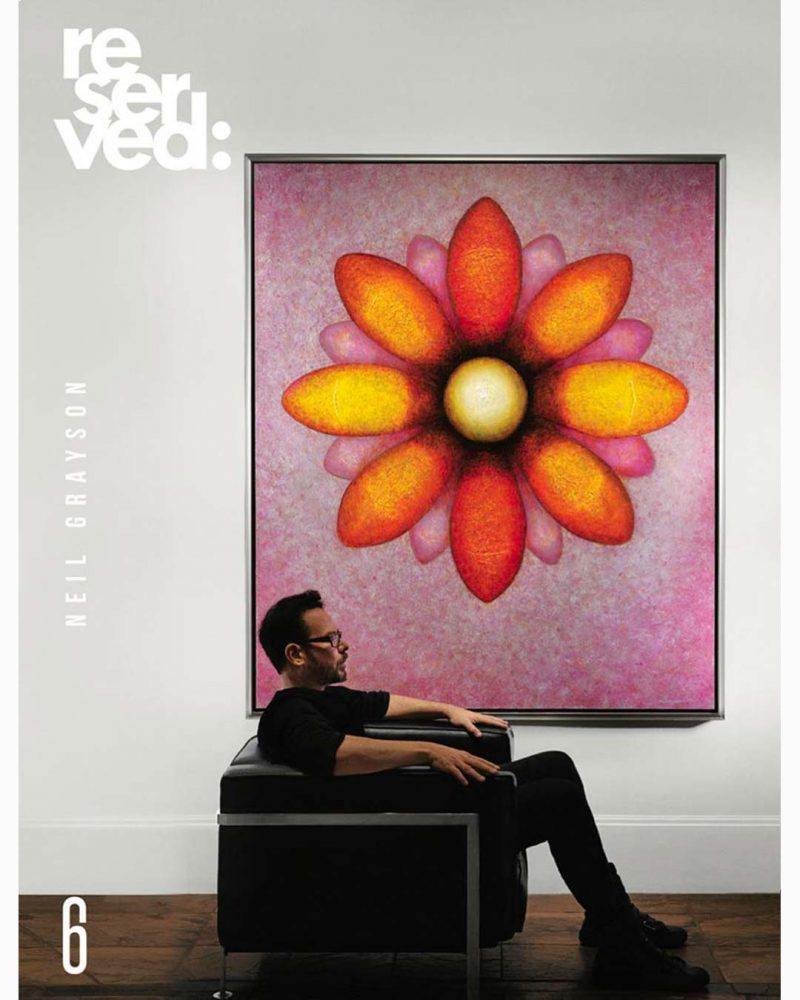

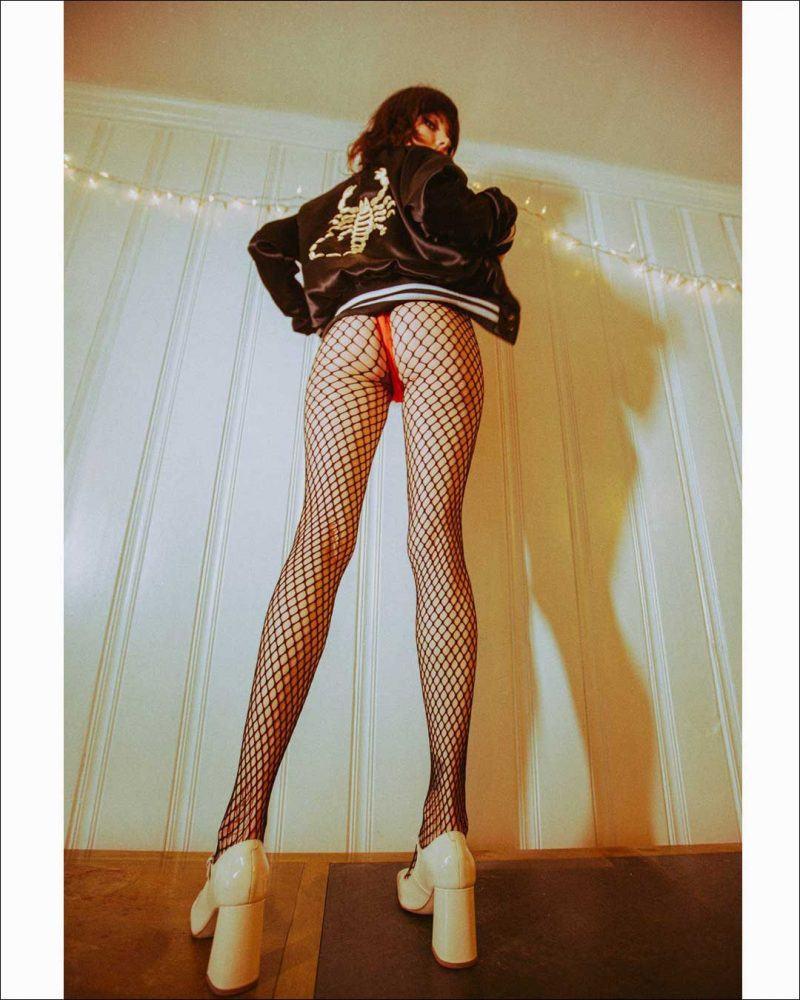

BJ Panda Bear – What type of adaptations and kind of what you’ve learned from working with United Nude that you have adopted into the process of, like, the new shoe and how sustainability is part of it?

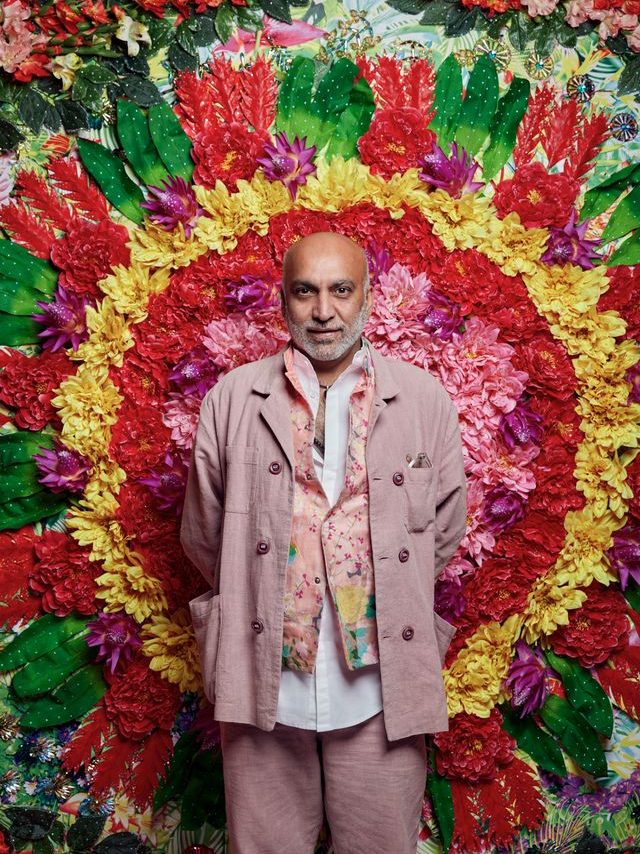

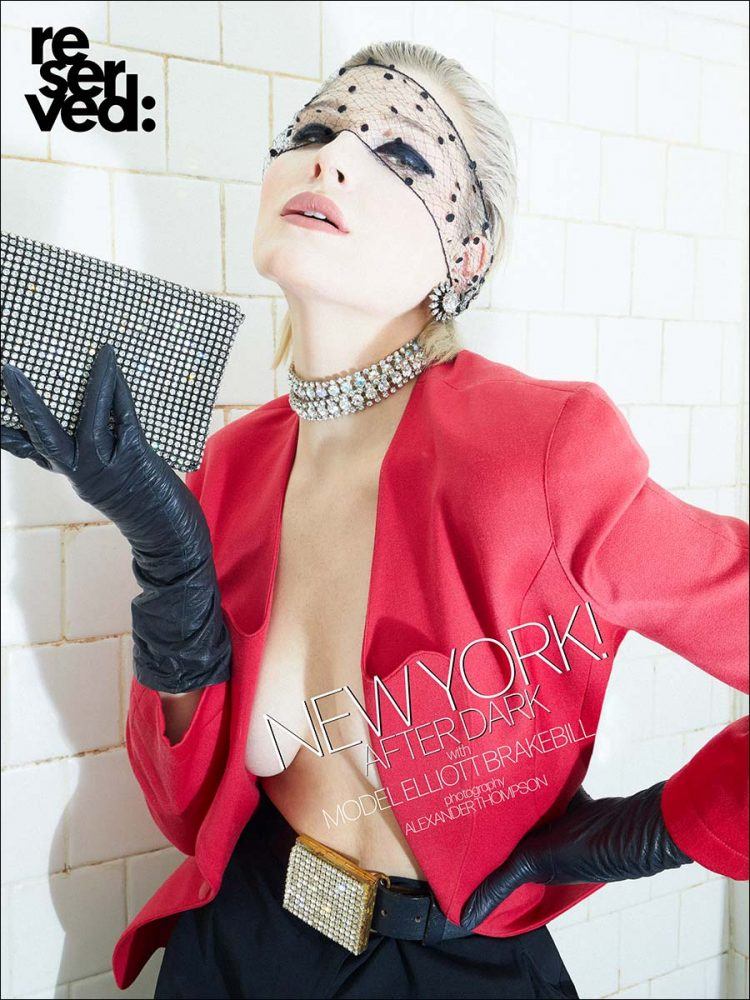

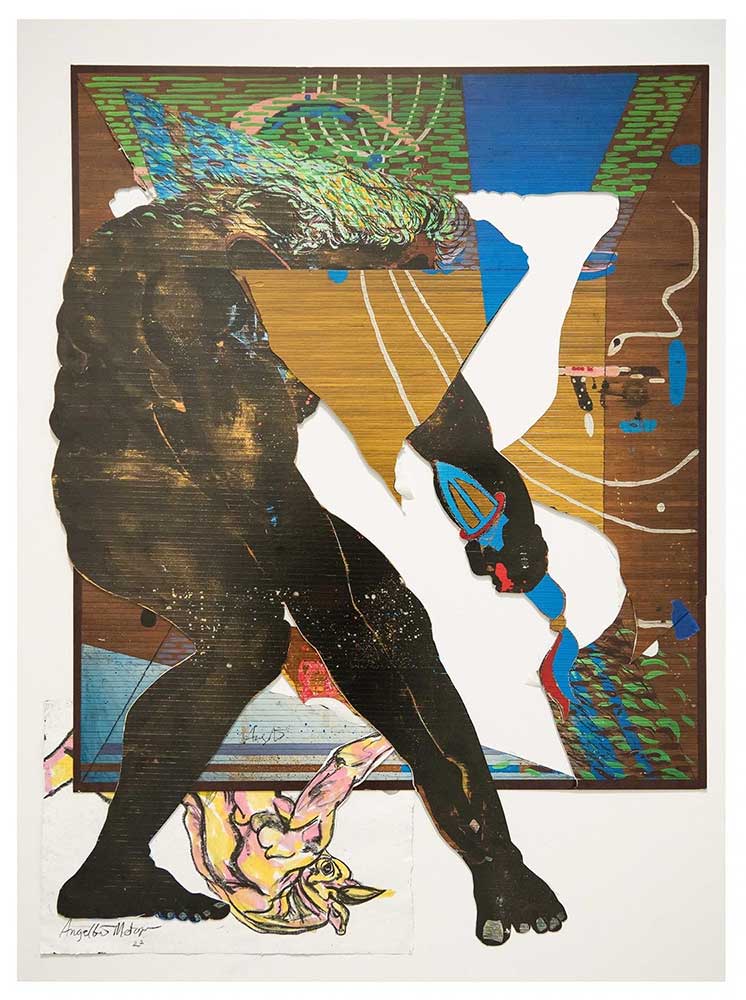

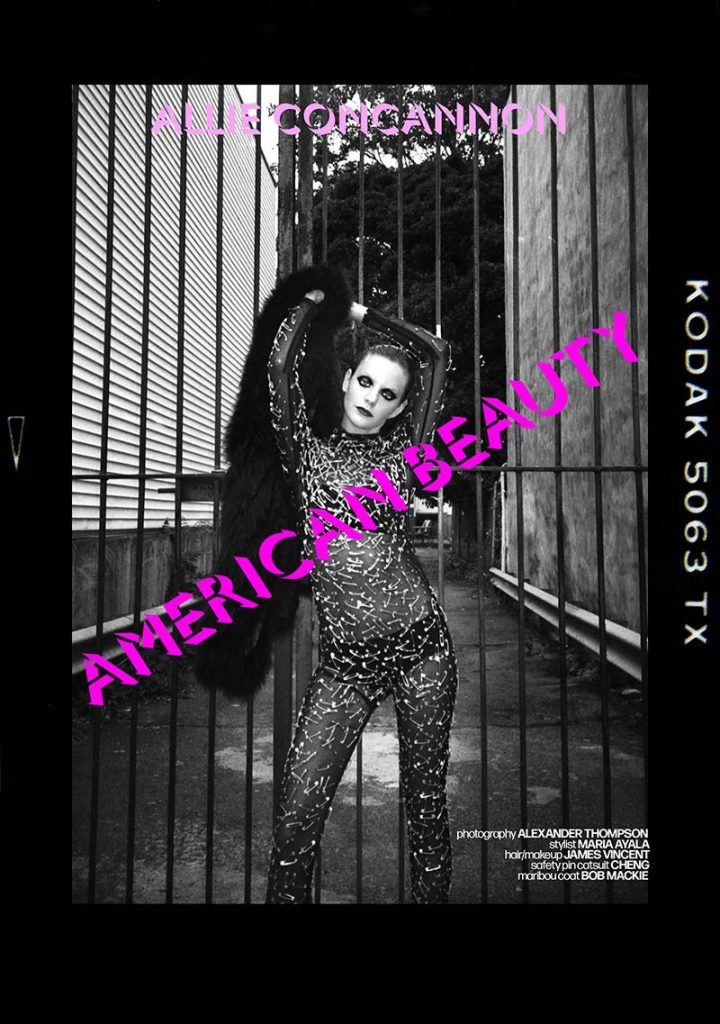

Rem D. Koolhaas – The brand KHOLA came about from a single question by the Issey Miyake team. We’ve made many collaborative footwears for Issey Miyake’s runway shows. The last meeting that we had after the show in Paris, we would sit down with them in their studio and have a meeting for the next season, and what does the future look like. I answered them briefly, saying, you know, that’s the shoes that we’re making. On the way back home I took a train back from Paris to Amsterdam, staying with my mother at the time. I repeated that question to myself, what does the shoe of the future look like? I started just writing down words of what it should consist of. Then one of the words should be sustainable. What does that mean for footwear? How do you make footwear most sustainable? Well, most sustainable footwear should not have glue, because the glue is the part that makes it very difficult to recycle or reuse or upcycle. It’s the dirtiest part in the whole process in the product. I then started sketching how I would make a glueless construction, and I basically sketched the construction that we’re making now. I thought, if I want to launch this, I should not launch it with United Nude, because it needs to sit on its own, it’s so different, and it’s all about this construction. I decided to start a new brand for it.

- Photo Courtesy KHOLA.

- Photo Courtesy KHOLA.

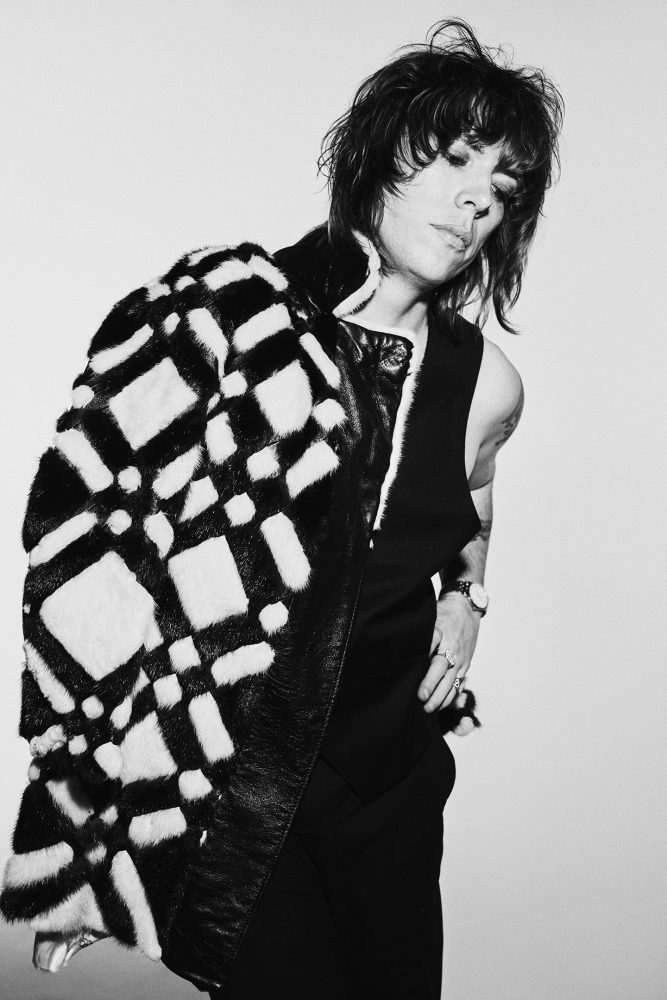

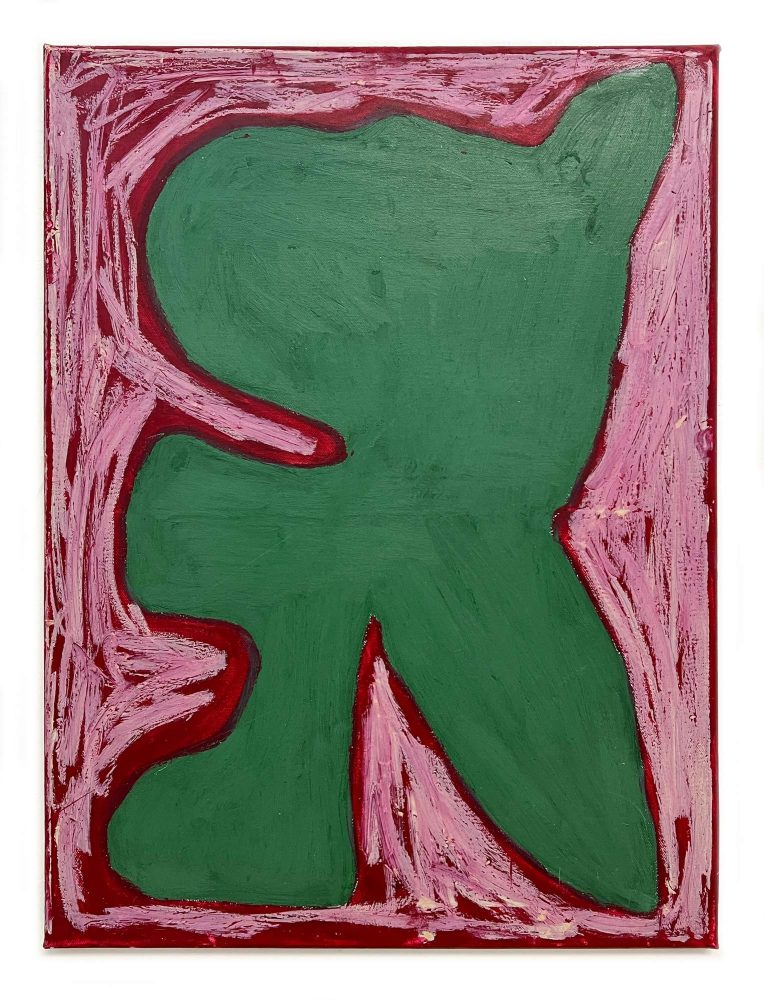

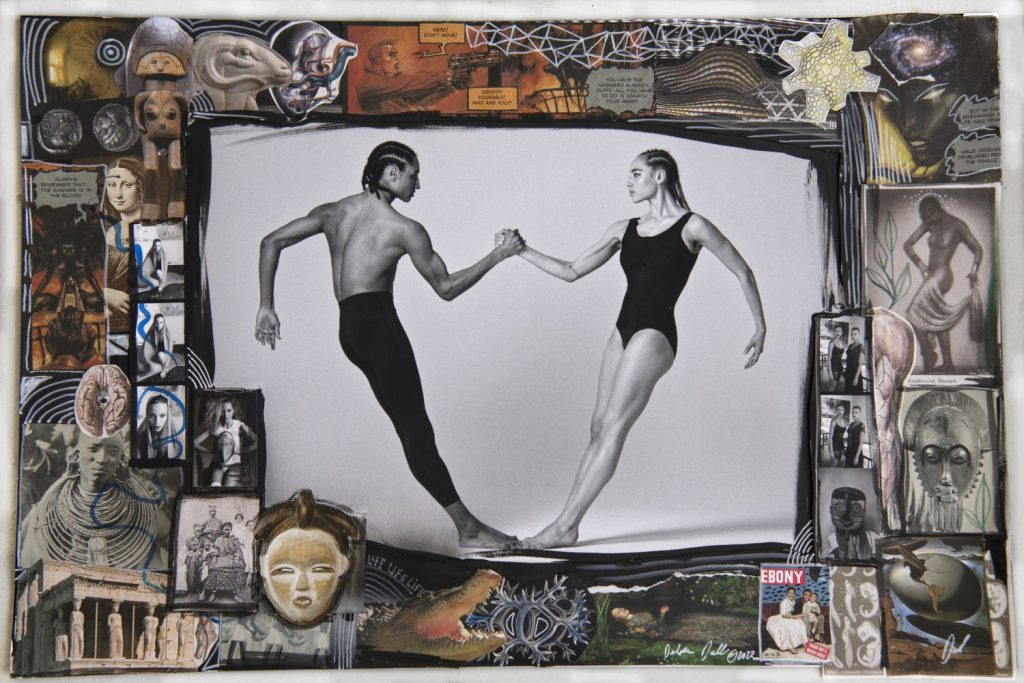

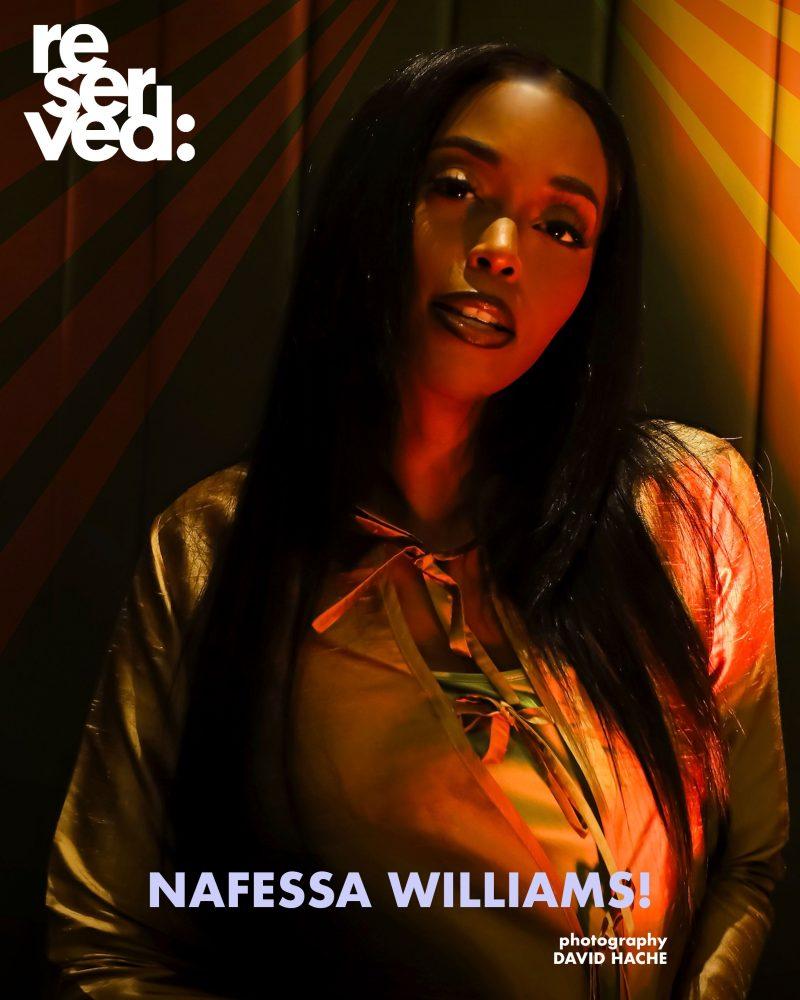

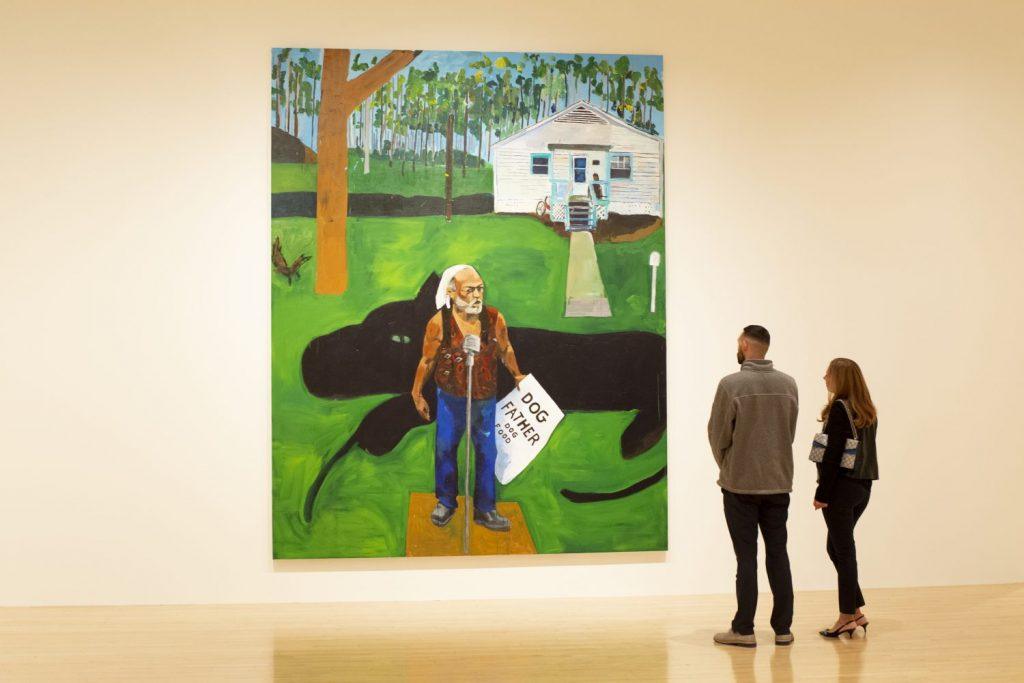

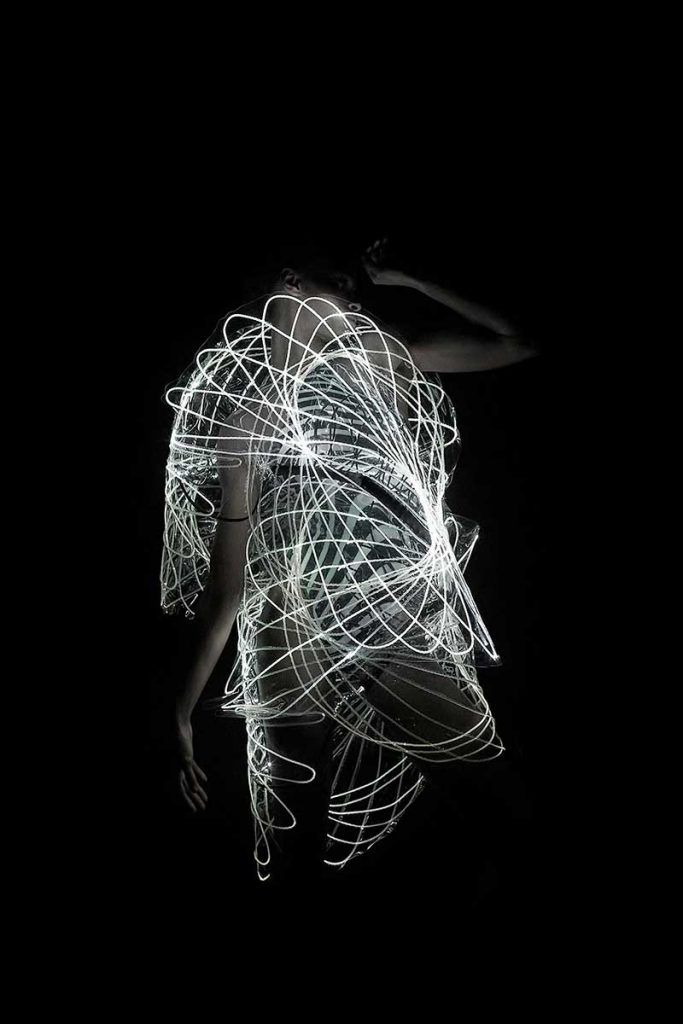

BJ – I feel like you are designing a product that is very much tied to a certain type of aesthetic that comes with sustainability. For the longest time there was this patchwork focus, and then we went into this need for almost, reshaping sustainable fabrics so they don’t look like where they actually came from, like Marine Serre. Now it’s back to this place where we acknowledge the past that these products lived.

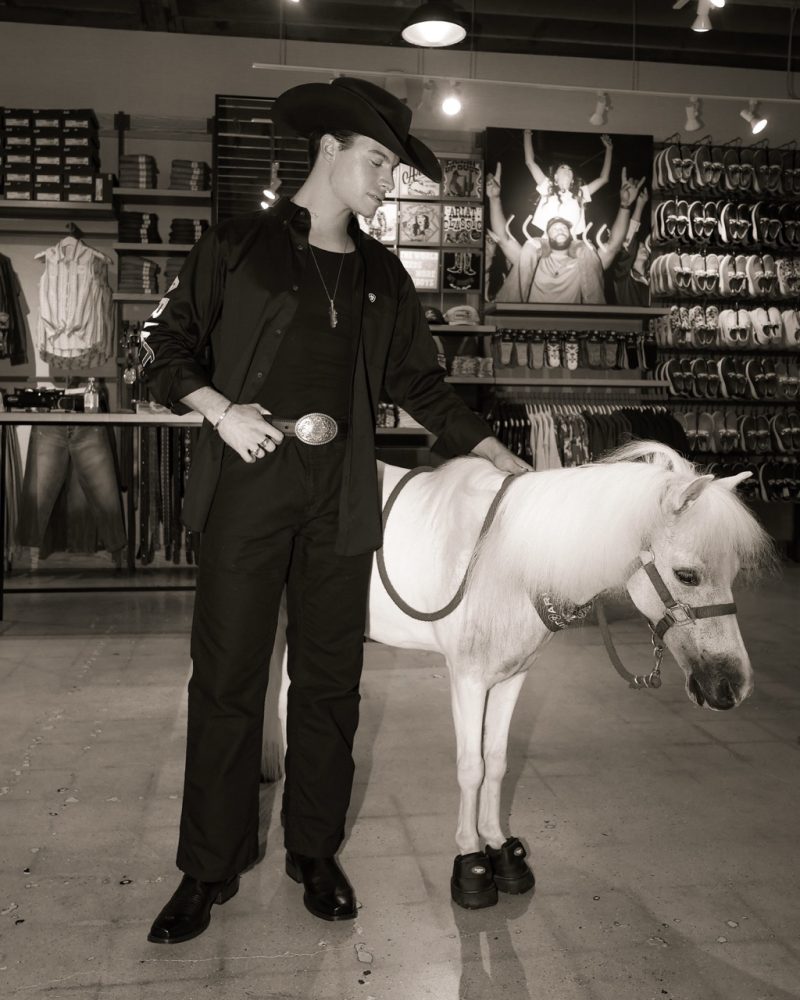

RDK – I was trained as an architect. I hold a master’s degree in architecture and engineering. My designs have always been about engineering. Coming up with this new footwear construction, this whole new assembly is more about engineering than about design. Almost like the engineering becomes the design. The form follows function, and the function is created by engineering, therefore form follows engineering. And that’s what this shoe is about. I think it has become a modern, simple sci fi look, and at the same time it looks like it’s already been there. It looks from the past and from the future. It’s so simple, and simplicity feels ancient.

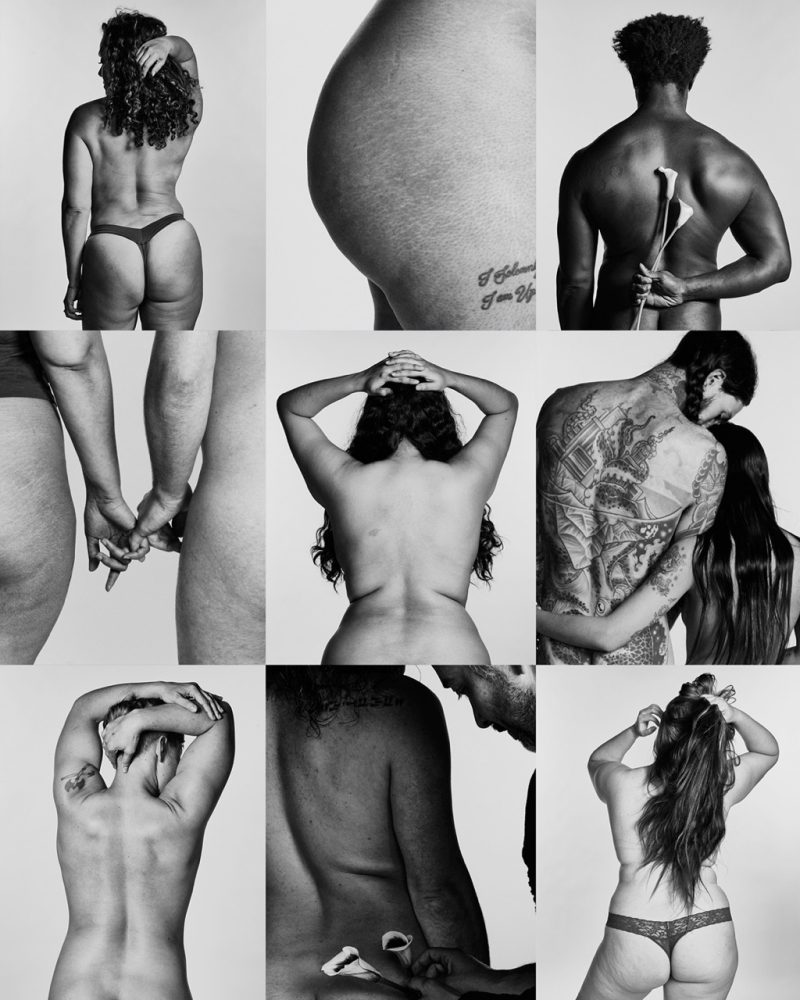

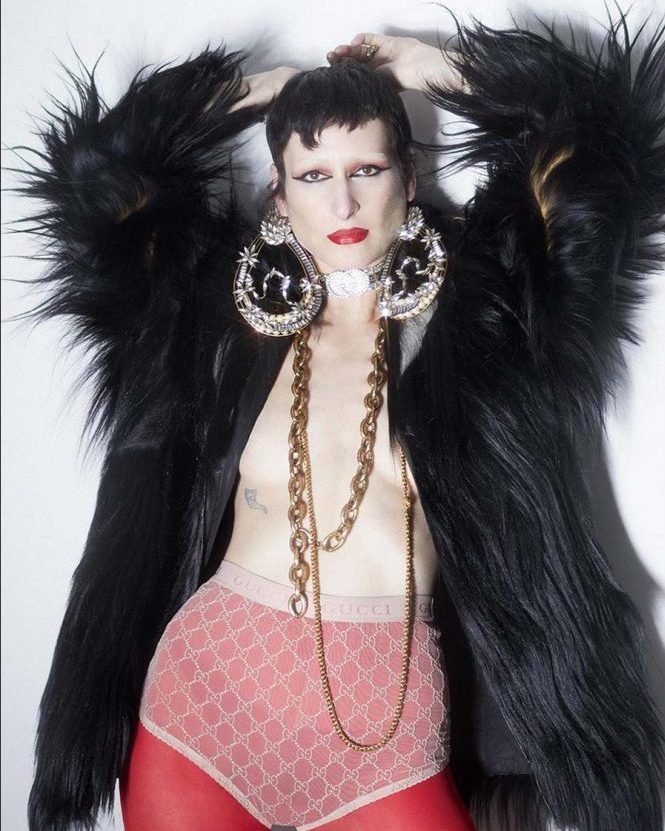

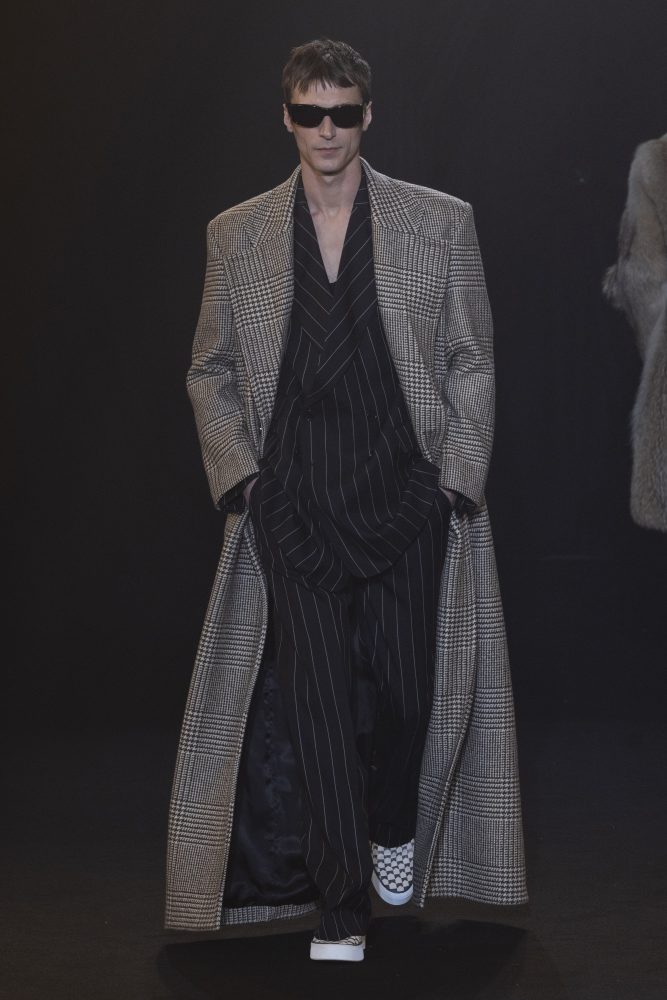

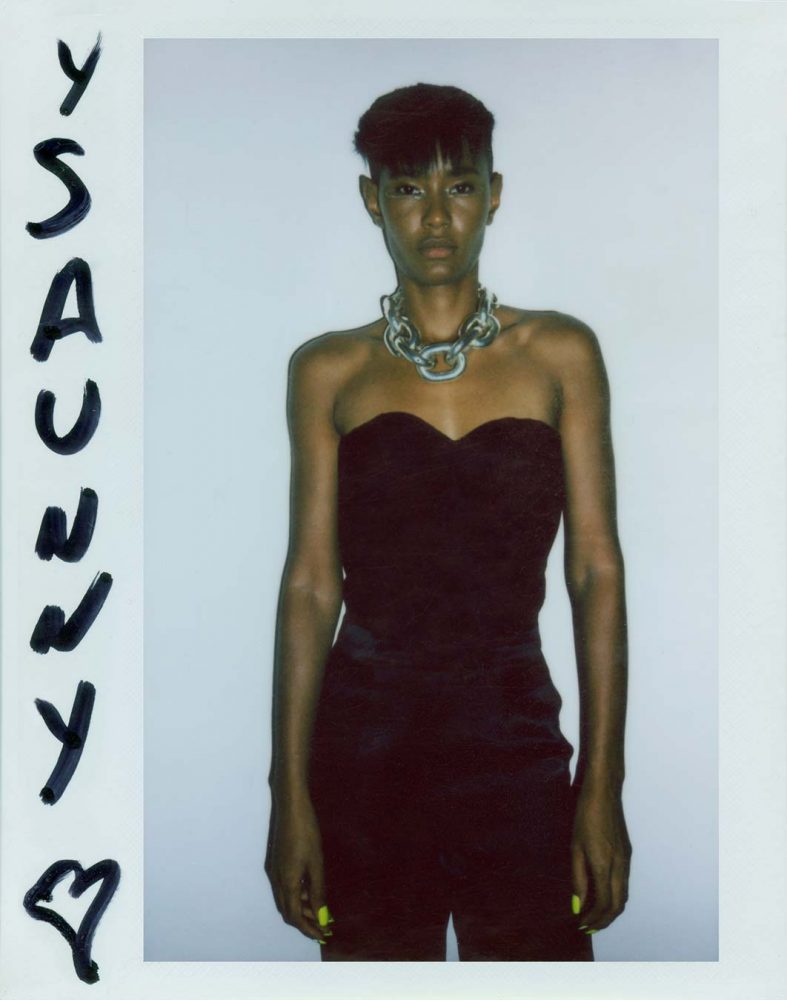

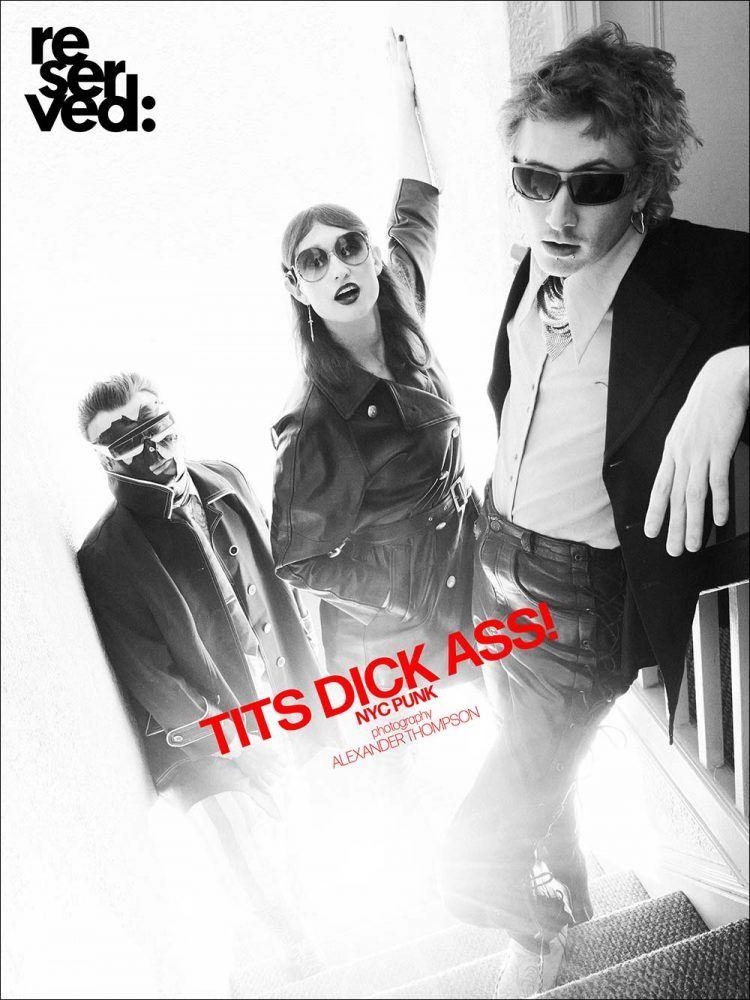

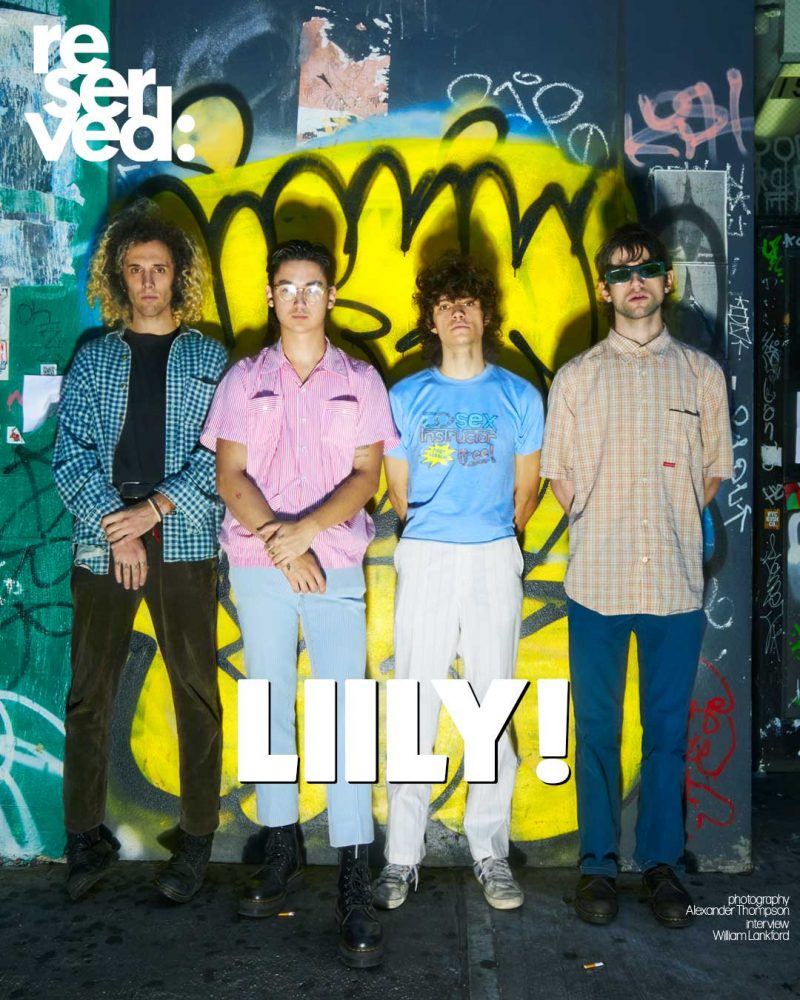

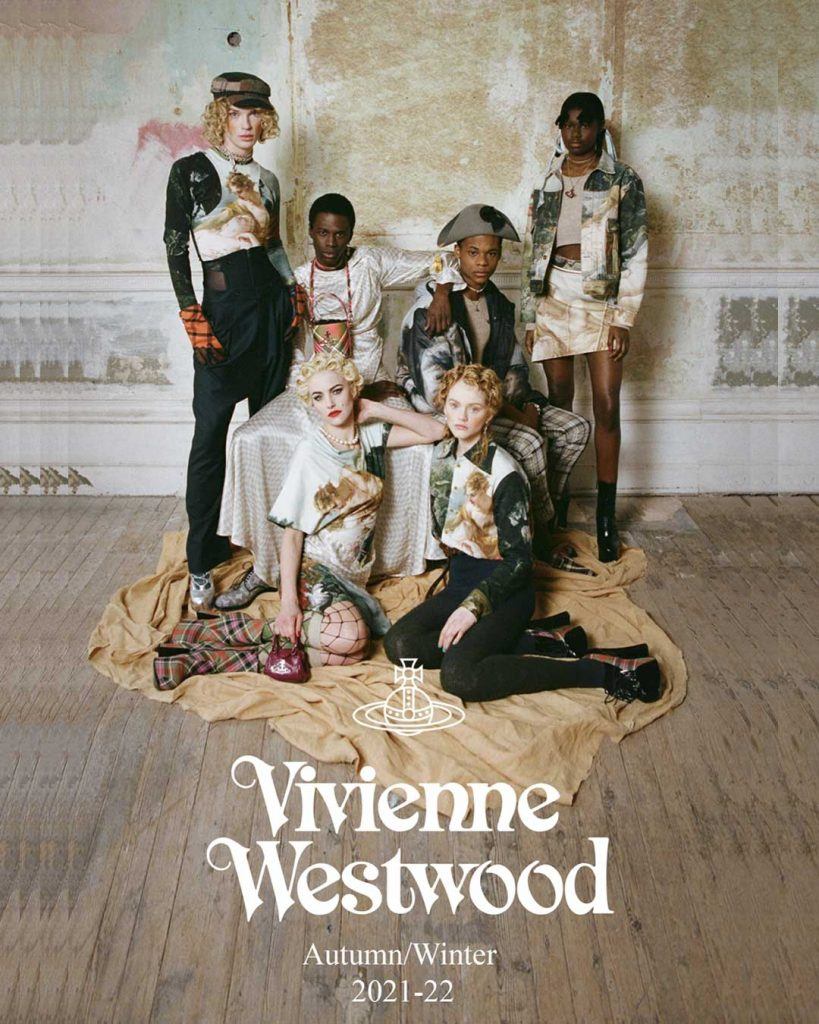

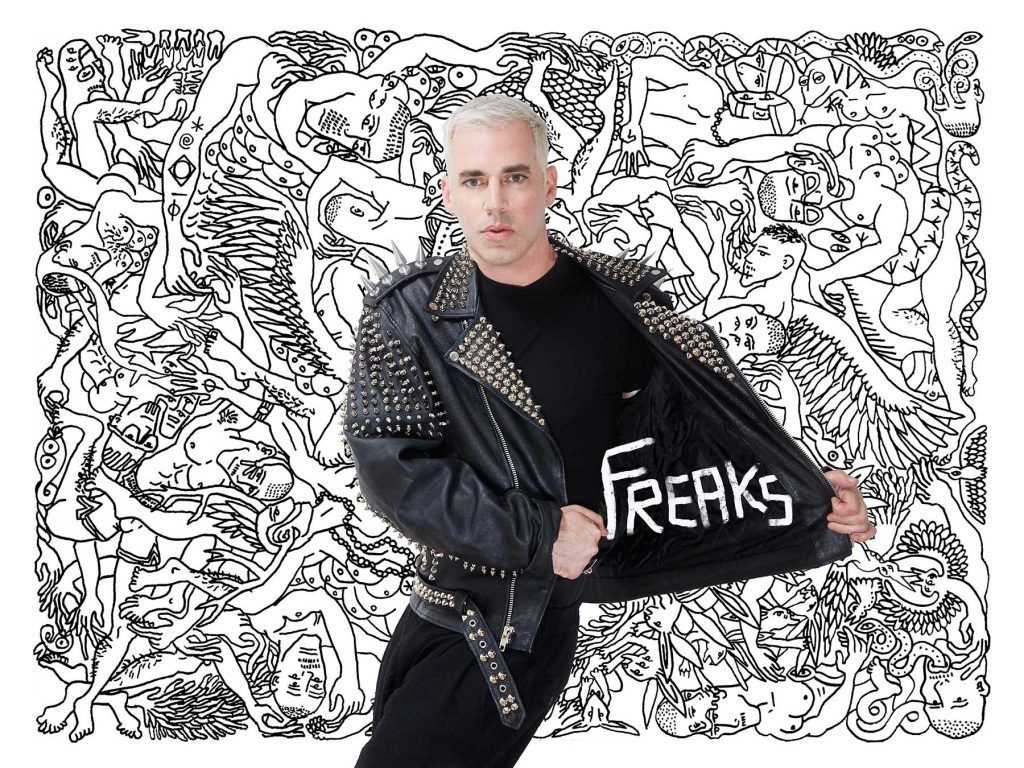

BJ – Has there been any thoughts about how you’re going possibly adopt some of the United Nude products into KHOLA?

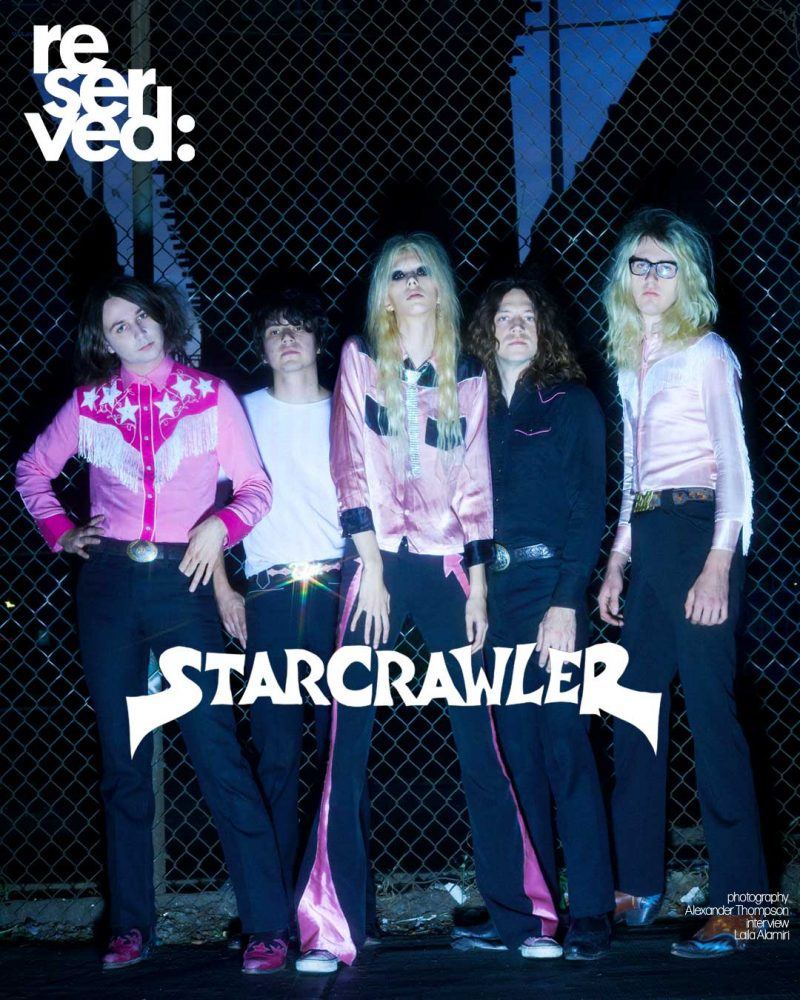

RDK – We’ve done a lot of tests with shoes where we take an existing shoe, and we cut the entire sole off. We did that with a lot of sample shoes creating prototypes with that. One of our services is to resole shoes for customer with their own shoes. We’ve done a few United Nude shoes like that as well, and they came out really good. In that way that’s the overlap with United Nude, but we don’t have a collaboration planned anytime soon. The brand KHOLA is very easy to collaborate with because the footwear construction is so flexible, and you don’t need a lot of tools. It is modular, but it’s also toolless. Usually when you make a shoe, you need a lot of tools. You need a tool for the lasting, for the buffing, for the for the gluing, for the pressing. All we all we need is a stitching machine and a hand cutter.

- Photo Courtesy KHOLA.

- Photo Courtesy KHOLA.

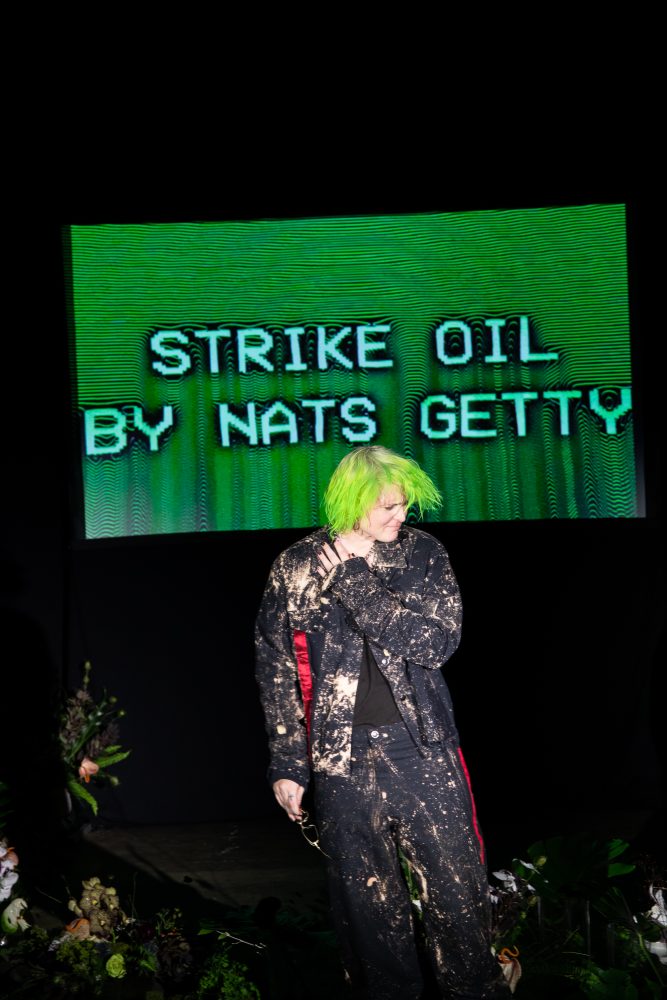

Jianno Voets – What you just said about us being modeler and toolless is one of our biggest strengths, because that makes the brand so diverse. Earlier today we were speaking about the fact that our brand allows almost everyone to collaborate. We call that “KHOLAB” and not just in a sense where people send us their old shoes, but also in a sense where young creators can design their own upper for our sole. A lot of people are not in a position where they can start a footwear brand, the soles are very complicated to make Our soles people can build off of that, I don’t think there’s anything similar to that. There’s so many factors that make KHOLA very unique and stand apart from existing brands, not just the sustainability but also the flexibility and creativity.

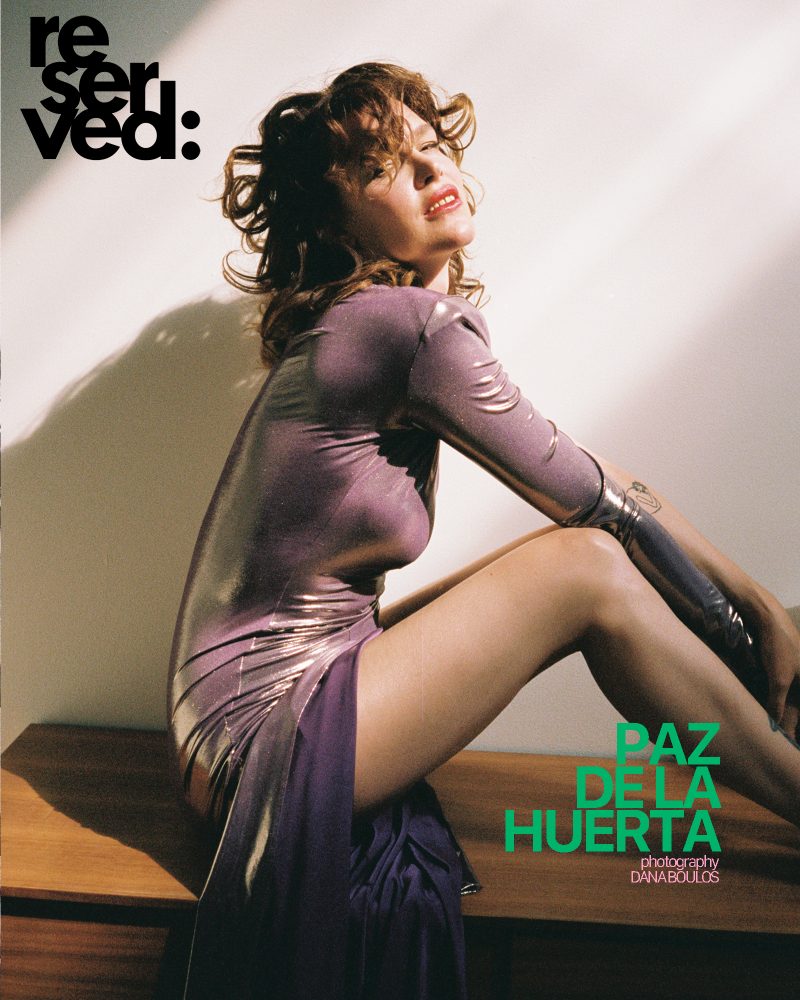

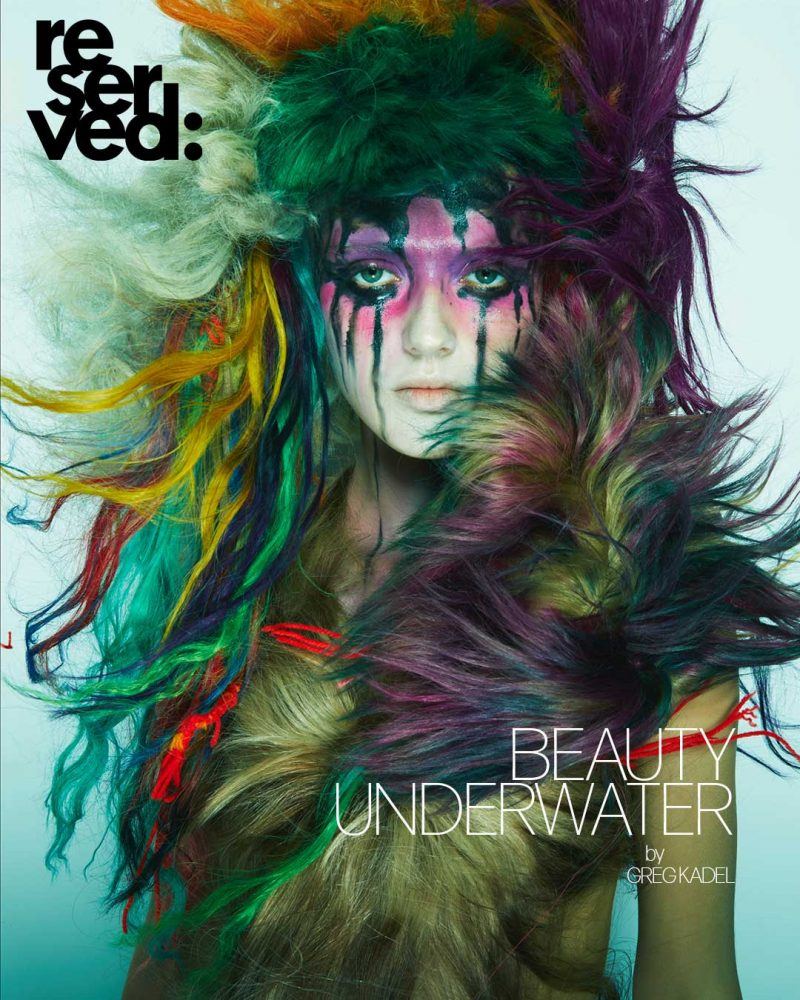

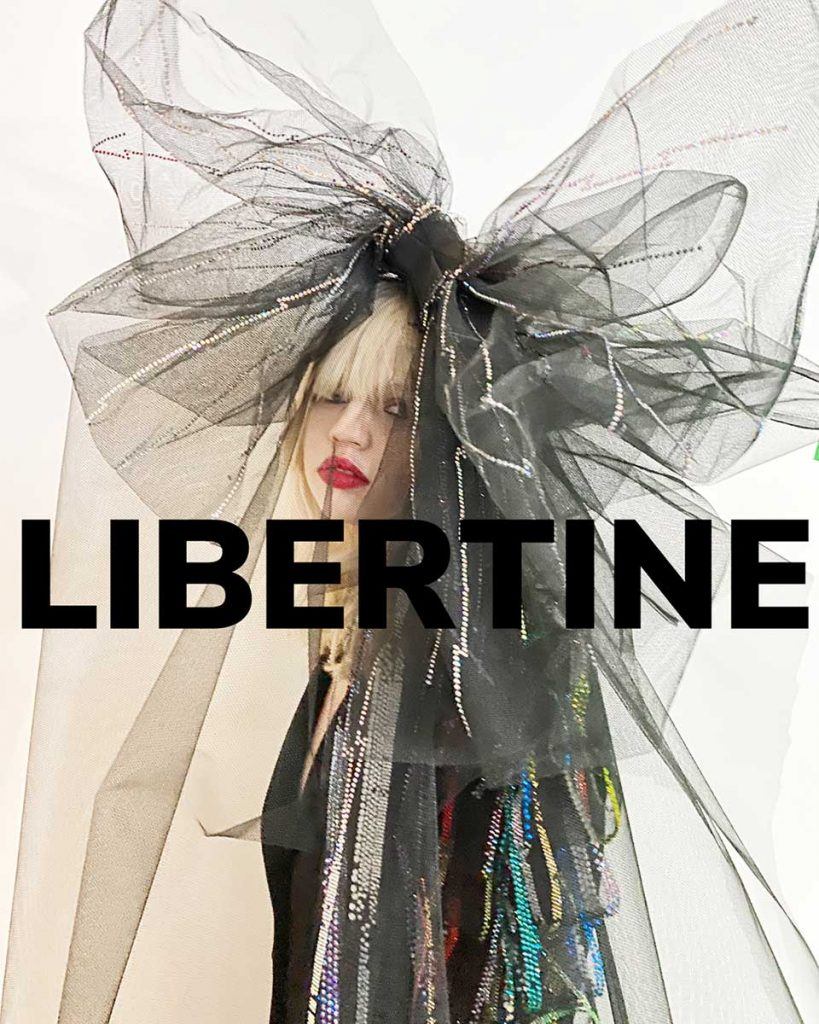

BJ – Your team is based and manufactured in LA, how important is it that you have it stateside, locally sourced and created?

RDK – We are offering it as a service for people here, it makes most sense to have that as close to home as possible. It’s all prototyping, it’s all one offs, especially in the beginning. If we scale it up, then we probably still would do that in LA, because it’s good to have it close by. It’s better for carbon footprint, moving the product around, and it feels great to be close to the actual process and to be in it. Manufacturing is a very cool thing; factories can be beautiful. Walking through a place where things are being made, either it’s a factory or a prototyping shop or a workshop or etc, it’s all super inspiring. There’re multiple reasons why it’s here. Maybe one day we’ll have local cobblers, and we do it locally for other places too. That could be a working model for the future where we would have something like that.

- Photo Courtesy KHOLA.

- Photo Courtesy KHOLA.

- Photo Courtesy KHOLA.